Question

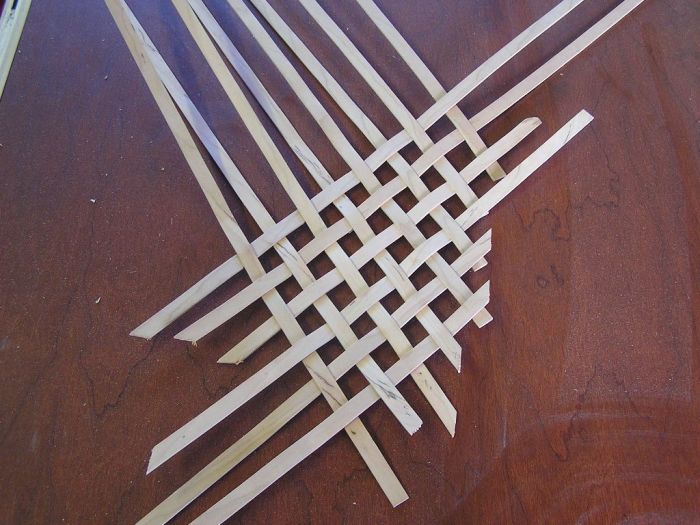

I've got an interesting project. My client wants some cabinet doors that are stile and rail construction with a woven wood panel (see photo). His yacht has some similar doors, and he wants to match them. That's fine, but the millwork on the yacht is all pear wood, which I can only assume is more flexible than the quarter-sawn cherry that I'm using for his house.

The pieces that make up the slats for the panel, which are 3/32 thick and 7/16 wide, keep snapping on me. The requirement is that I make the holes between the slats 5/8 x 5/8. At first I thought that this would not be a problem, but it's proving to be a challenge. 1" x 1" holes would be easy, but my client really wants 5/8 x 5/8. What happens is that I get so far along and then one of the pieces breaks, thus forcing me to disassemble a portion of the panel and start again.

My initial attempt was with quarter sawn cherry. I then went to flat sawn, which seemed to bend easier, but still broke often. I then steamed the pieces for 1/2 hour and put them in a form, which bends them into a wavy shape. This method shows some promise, but many of my pieces break in the jig, so it's slow going. I know that cherry is not one of the more bendable woods. My client might be alright with something else if it will take the stain in a similar way to the cherry. He doesn't want to decrease the dimension of the slats, and he doesn't want to increase the dimensions of the holes. I'm currently looking into getting my hands on some pear wood, but any suggestions would be much appreciated.

Forum Responses

(Architectural Woodworking Forum)

From contributor H:

Your client needs a physics lesson. You can't have the day time and the night time at the same time. You/he will have to give up thickness in the weave or size of the hole. Try 1/16 X 7/16 . Make a sample. Show it to him. Don't tell him the thickness has been reduced until he asks how you finally did it.