Question

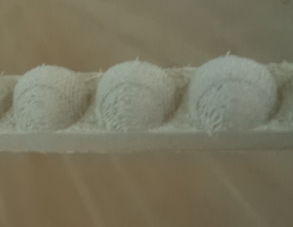

We have a CNC supplier cutting the moulding below for us. We have found that we must do a great deal of hand sanding to remove the fuzzy around the bottom edge of the ball surface. Is this a problem caused by the CNC program? Is it cutting speed, tooling or etc.? Maybe it is because we are using yellow poplar and should have used soft maple or beech? I would appreciate some help from people that are experienced in this area. I am not sure how much I can trust the CNC supplier to solve this.

Forum Responses

(CNC Forum)

From contributor N:

The fuzz is likely one of three things. The material does make a difference. Poplar does fuzz up, especially with cuts against the grain as your photo indicates. You will get less with a tighter grain material, but will not eliminate it. The CNC people could go with a smaller diameter cutter, but that would increase the run time significantly. Beaded molding of this type is really tough. The best cut strategy to reduce fuzz is to cut perpendicular to the grain, but on a bead this will leave tool marks. So to reduce tool marks you switch the cutting strategy to a sprial cut path. This eliminates the tool marks, but leaves fuzz. I don't hand sand my work, I use star wheel sanders on a drill.180 grit followed by 220. The photo below is cut in cherry. On a personal note, I would not ship a product with fuzz, but one gets what he/she is willing to pay for. Ask your supplier what it would cost per foot to have them sand if capacity on your end is an issue.