Ok, I've owned my cabinet shop for about 3 years now. I bought it as the owner retired and he made all of the cabinets for my custom home/remodeling business. I spent 2 years learning the business and understanding if I could make it profitable and like it. Turns out I loved the business so much I've all but quit building (that's 26 years worth ). Problem is I lost my shop foreman to cancer about a year ago...didn't realize how good he was. We are a smaller shop 2-4 employees but I've really struggled finding anyone who wants to work! We do about $300k in sales and I'd like to grow, not just to grow but I know I can't stand still. After going through 6 different lead men I'm seriously considering shrinking our volume and staying focused as a small high end quality shop with just myself and my trusty finish man. Who's do cost/ feasibility studies on growing vs. shrinking . My strength is sales but I have a fine carpentry background and would be just as happy being a shop rat.

From contributor Ch

I do not have any statistical evidence. This is just my opinion based on my observations of my own shop and some others around the country.

1) Raise your prices. (More profit. Isn't that why we are in business? Maybe not the only reason, but it ranks pretty high for me.) That should reduce the volume a bit. If it doesn't you might need to raise them again. I am not saying gigantic leaps each time. Maybe a few percent now and watch the results for a number of months or so. Also, try to learn whatever you can about your competition's pricing and quality. You are already ahead of a lot of shops by only offering wood and no particle board. That attracts folks who want and are willing to pay more for quality.

2) Get a CNC. Learn the software and the machine. Throughput can increase and quality can improve. Both can happen without adding personnel. In fact, you may be able to reduce personnel.

3) Take very, very good care of your finisher. You can do sales and marketing. You can play "shop rat" all you want. You can order materials, CNC parts, edgeband, assemble, and do lots of other things. But, finishing is very time consuming. A basic rule of thumb for relatively straight-forward projects in my shop is that the finishing will take about one-half of the hours budgeted. That includes selling the job, and all of the things I listed above. You don't want to lose a great finisher. If you have to do the finishing your shop throughput will likely be cut in half.

From contributor da

Why do you need a lead man? Just get some good competent workers that have great attitudes, some experience, and will follow directions. Then supervise. Be a great supervisor. When people stick around, they really don't need much supervising, so you can add more people.

You just can't grow in leaps and bounds this way. You just are creating a core, and continually adding to it.

From contributor In

Thanks for the responses. Maybe hiring a lead man is the wrong term. I've tried hiring with no cabinet shop experience, and with lots of cabinet shop experience. The reality I'm beginning to understand is our labor force is pathetic. I need someone with a willing spirit, who is detail oriented and able to machine boxes. I'll keep looking but I'm afraid I'm at a crossroads where I need to understand. What to do. I've done the math on a cnc machine and understand how it works and can be beneficial but I don't want to raise overhead at this point. I have some other pieces I need to add currently. Raising prices is definitely in order and on the last two large projects I charged premium rates. I'm at the point where I'm going to miss ship dates which I simply don't do.

Who has kept it small and still been able to earn $100k? That's where I want to be to be long term viable. I'm not there yet but it's the goal. Ideally I'd like to be about a five man shop with two builders, two finishers, and a general helper. Yore right about the finisher. It's taken two years but his like gold to me now, I even provide an apartment for him above the shop as part of his compensation.

From contributor ja

"when you can't be with the one you love Honey, Love the one you're with" CSNY

I agree with Dave we run six plus me stable they trust I keep them job safe, I trust they get the work out the door "Finished" and keep the reputation High. been doin this a long time,, takes time but it has proven worthwile,, all are cross trained, all have strengths over each other, all depend on each other

Including me

From contributor ca

Indy-

What you are needing to do is set SOP's. "This is how we do it here", "and there really is no other way". It takes time, but the paperwork from the office can and will start and finish (along with "your" supervision) jobs better than you being out in the mix as a shop rat. Your company can build items for the shop that allows the employees to see the work you expect, and educate them on the finished product, like wall storage cabinets.

I think you need to get "lead or foreman" out of your vocabulary for the time being and cross train like heck. A foreman or lead will step up naturally. I think Jim states it well. Their jobs are to get it out and your is to get it in. You are at a huge advantage over other owners as you have the solutions skill set from being a trim carpenter and know exactly what you need in the field to execute a great/successful job. You need to use this to your advantage.

I have a great friend that lost his job as a car dealership general manager, he fell into a manager @ lawn care facility and has slowly cleaned house, setting standards and operating procedures, they pull in people from "Labor Ready" or college students regularly and get their work done more efficiently and more professional ever than before. We are doing the same thing here. It comes from the office, not a lead guy or foreman. Once the office sets the standard, a lead guy or foreman will materialize and grow into the position naturally and the whole crew can work that much more efficiently.

Yes, 100k out is easily accomplished, but I think it may take time to get your machine churning productively and once you get the momentum going, it should become rather fluid, both in production and cash generation.

I hope this helps

From contributor Ti

thanks all for the responses. It does help. You guys have all touched on processes I've worked on but not yet completed. I have began setting up SOPs. It does help. Every person who is in the shop, including me, is required to perform any task necessary to meet the end goal which is ship date. If that means sweeping floors, sanding doors for the finisher, or ripping sheets of plywood that's what happens. It is a bit of a double edged sword for me because I've always been the one person who is the most efficient in the shop, but at the same time the minute I get in the shop, my labor rate is the most expensive and I'm not selling, keeping inventory up, etc., and the process gets derailed.

We have a process for building cabinets and anyone with a good set of skills can build them. It's the speciality items that get us in trouble, those are also the items that differentiate us and can be the most profitable. I learned the hard lesson about cross training and work to make sure everyone has some experience at all facets. I think Dave and James are correct and I need to focus more on the person rather than experience set coming in.

From contributor pa

In business I think it takes a irreducible quantity of 2, one to drive work into the shop and one to drive work out of the shop.

The prior is more important.

This might be a good time to do as you stated and work on organization. You might read a book called the E-myth regarding this as well as check out Lean manufacturing.

I'm currently reading a book about business cycles.

In it he says:

Here is the forecast in a nutshell. The construction industry in 2014 will under perform 2013. Nonresidential work will outperform residential construction. Housing and the economy in general will improve in 2015, especially in the latter half of the year. STAFDA members will be busier in 2015 than they were in 2014. You will be busier still in 2016. A lack of preparedness in 2014 will mean lost opportunities in the latter years.

Here:

http://www.contractorsupplymagazine.com/pages/Current-Issue---A

lan-Beaulieu-10-11-2013.php

Also consider that at some point economic factors are going to impinge heavily. Not the least of which is demographics, debt, international trade, automation.

The boomers are 50-68 more or less. With most of the kitchens being purchase between the ages of 50 and 60. Commercial work follows residential work so I would look at your area to see how strong the residential segment has been. And look at what percentage of those sales have been investors.

At some point the debt will impact the economy but probably not for 15 yr or so.

There is a re-balancing of international trade because China is no longer going to be growing their exports. This means that after 2 or 3 decades the US is going to be doing more manufacturing as are other countries. The biggest export will be oil as the US is projected to produce as much oil as Saudi Arabia. Since the cost of oil impacts the cost of everything it will make US products cheaper.

Automation always drives up the standard of living and reduces the cost of goods. Trade always drives up the standard of living and reduces the cost of goods. The pertinent point is always be automating.

From contributor Ke

I think you underestimate the cost of cnc help and overestimate the actual cnc cost. My machine has paid for itself many times over. A mid size 30-40k dollar machine new can be bought used for 15k or so as well. This size machine can run a kitchen worth of parts a day easily. When the machine is cutting parts, I am banding and assembling. The cost of one man for one year will pay for a decent cnc. It will pay for itself in a year and make you an extra 30-40k a year in profit after that.

Do as you wish, but entering a cabinet size, and pushing the go button on the machine really is nice. On top of that it is free, because it makes more than it cost.

Ken

From contributor La

Finding a great lead man, I have no clue. I hired mine when he was no longer happy @ another rather poorly run shop. He had been here and applied. As for CNC in a small kitchen shop, it can be a winner. You will need a cabinet program to quickly get the jobs out to it. That transfers some of the shop work to the office but saves time. I'm not sure I'd recommend a used CNC if you have no experience. A CNC will save a lot of assembly time. To get maximum benefit from it you will probably want to invest in some additional equipment and maybe change your thinking in terms of materials. Routers are very accurate, that advantage can be lost if you are using variable thickness/ flatness material. l think most shops running routers are Euro box shops. It is a very efficient system when fully embraced.

It seems few small shops take full advantage of the system. At this point keep looking for good help and I'd hold off making a decision on CNC until you attend IWF2014.

From contributor In

Thanks again for the responses . It's difficult to relay the info necessary to really make a decision that's right for any business. I see us purchasing a cnc a some point but I am also a firm believer in a cash operation, I'm not ready for it. Even though our building is massive we barely have enough power to run the equipment we own so that's step one. I've have to run phase converters for three phase and the power we get isn't suitable for sensitive equipment.

But, not to stray from the topic too far but we are still learning what the best mix of product is to off and consistently make a profit. We only build euro boxes from 3/4 " domestic plywood. It's just what my market is asking for currently not what I necessarily think is best, although the cabinets are beautiful. With the tooling I have I can easily cut, edgeband, line bore and have a kitchen ready for paint in a day. We paint it all flat before assembly. It's more about the system, it's takes a little while to teach someone but that just it I can't find anyone willing to work that has a brain. It takes both of those. A willingness and a brain. Even though you have a cnc machine you can really jack up some expensive board/machinery with the wrong person. I think for now I'm stuck being patient for the right person and I'll grow when I'm able.

The labor force out there is really disheartening. I would love to bring up a young man in the trade, give him a skill set and let him grow. I have yet to find one with a work ethic that warrants my time. These kids all want to start at the top and make top pay, without the hard work it takes to get there. I'm tired of hearing about all their money troubles or the inability to find a job to support themselves. When you offer them one the next comment is "I don't work Saturdays " some other lame excuse that equates to not working. I'm all for being flexible with a schedule if necessary but you still gotta put the time in. These jobs don't fit in a nice little 9-5 box. The last young man had a great ability to learn quick and a wonderful skill set. He was late three days in the two weeks he worked, and the last day he worked he rolled in an hour late, and asked if anything was wrong, he said he needed a $10,000 raise(he was training at $18/hr plus another $ 200/month towards benefits). I laughed, he got pissed and I issued him his last check. I never realized that personnel would be my largest single problem with this business. Ugh!!

From contributor pa

Indywoods

It seems odd to me that you seem to already have the answer yet you can only complain about the work force?

Most guys have gone to cnc, the cost of which is less than your cheapest employee?

I would say that the biggest advantage to this is that it reduces assembly time.

It is hard to do but you need to change your perspective and look at the bigger picture as your current perspective is not working.

Again you might look at the Emyth, Lean, and the one I'm reading about business cycles. (This the same economist that Stiles uses)

From contributor da

The average temperature for the nation does very little to tell me what the weather is like in my backyard. Related, yes, but not terribly helpful. Same for the economy.

From contributor pa

"The average temperature for the nation does very little to tell me what the weather is like in my backyard. Related, yes, but not terribly helpful. Same for the economy."

Good point but who was not effected by 9/11 or 2008?

The point about economics is prediction. If it was irrelevant than why use it?

From the book "According to the data we have received from a wide variety of businesses , almost all companies can rely on leading indicators to accurately forecast future changes."

The author claims 94.7% accuracy on his website.

http://itreconomics.com/why-itr

Or you can sequester yourself elusively to empirical data and patronize all outside knowledge as "not terribly helpful"

From contributor Ca

How does CNC help this guy?

CNC may be cheaper than the least experienced guy he could hire but even if the things that CNC does well were free he would still have all his other problems to solve.

Look a the work that's on his website. The box part is about exactly 10%. Getting decisions out his customer is probably 40%. A $5000 investment into a decent camera and lens would make him a lot more money than any CNC machine. Spend the time it takes to get good at CNC and learn how to take a picture.

The problem with CNC is that the place you spend most of your life always sounds like a mosquito on steroids. That's got to have some long term impact on cognitive. If you played a lot of football in high school AND ran a CNC shop you're going to be making new friends every day when you get older.

From contributor Ti

Wow, seems to be a bit off track. Didn't mean to get everyone so fired up and critical of my business. I appreciate the responses. Sorry you don't like my website. I never ever think I have the right answer for everything or am closed minded enough to consider a change. Change is inevitable. I've read the books mentioned, they can help to expand the thoughts but I don't hold anything as gospel. If had the answer I wouldn't be asking the questions. Someone will always figure out a way to make money and do what we do regardless of economy, labor, etc, etc. I had hoped for some examples of success stories and different takes at the cabinet shop business model. The only thing I am sure of is a business really cannot remain the same it will change, it will grow or shrink but holding the status isn't an option.

From contributor Ca

I didn't say I didn't like your website.

I said you, and most woodworkers, would benefit from learning how to better market their work.

The fundamental premise of lean thinking is that you want to focus on things the customer values. When your customer is getting ready to pull the trigger on buying new cabinets they are hungry for information. They don't care whether you use a CNC to build your cabinets or whether you sprinkle pixie dust to make it happen. They do care about pictures.

Your work is very good. You don't represent it as well as you should.

From contributor ca

Hey Tim !

This is good. I learned a lot over the years from this forum and I am a great success story.

I started asking questions 9 years ago and got bashed severely when I reduced my "work in progress" a few years ago to get in control of my processes and shop. And, announced what an improvement it made. I had 1 employee. Today I have 8 and a full time business manager and a drafter that kicks a...... I owe some of my success to these others analyzing your operation with a microscope.

Oh well, a lot of good thoughts on this thread, best of luck.

From contributor Ca

Cabinetmaker makes a good point.

The easiest way to get more work done is to do less of it.............at a time.

You know how building a kitchen with 30 cabinets almost swamps your boat but you can spank out a 3 box bathroom vanity without even breathing hard?Reducing your work in progress in progress does the same thing.

Turn that 30 box kitchen into ten bathroom vanities and you'll create a lot of excess capacity immediately without writing a check to make it happen.

From contributor da

I guess you made my point, Pat.

Except for broad generalities, I know of no one that predicted 9/11 or the timing and scope of the recession.

If ITR is 94.7% accurate, I hope an unbiased third party confirms it, and that Janet Yellen then uses their services for the good of the country.

I know they do not predict when my customers decide to retire, or when a competitor decides to give away their work, or when my electric company decides to increase rates. We do not do business on a national scale. There is no aspect of my business that I would change even with a 100% accurate 12 month economic forecast. I venture to guess most wood shops are in a similar situation. Not all. Most.

Here's my forecast for my own situation: more work than I can handle till I retire in 15 years, with occational moderate to severe interruptions. Motto - be prepared.

Don't know how you assume I patronize all outside knowledge. You found a source that you believe in, but haven't completed the sale to me, and possibly others on woodweb.

Forecasts are most helpful in the time frames they are least accurate - the distant future. Knowing that the economy will be strong next month or in 3 months is something I could have told you from my own readings of the situation. If ITR says they are 95% correct 12 months out - I would have to see an independent evaluation to believe it. My trash guy also says he will be on time. Seeing is believing. 95% of what? GDP growth? Unemployment? Trade deficit? Change in seats in the House of Representatives? 100% accurate 95% of the time? Or 95% accurate 100% of the time?

Pat, I could go on at length about many of my well thought out beliefs, but you are no more likely to jump on them than I am to jump on your beliefs. That doesn't mean they aren't good ideas, but I think it is wise to be cautious about jumping on new beliefs.

Apologies to the OP for getting off the discussion.

From contributor pa

dave

And few predicted 2008 either. But is was VERY PREDICTABLE.

I predict that Yellin will do the same as her predecessor.

"I know they do not predict when my customers decide to retire, or when a competitor decides to give away their work, or when my electric company decides to increase rates. We do not do business on a national scale. There is no aspect of my business that I would change even with a 100% accurate 12 month economic forecast. I venture to guess most wood shops are in a similar situation. Not all. Most."

Sure they do.

I used to do this 30 years ago when I did residential at which time I determined that people buy kitchen remodels between the ages of 50 and 60.

I don't care if you buy anything. The OP was asking how to improve his situation.

Most shop I know have invested in CNC because it improves their productivity. Most shops I know do some type of forecasting. Most shops I know have used Lean. Many shops I know have used the E-myth.

Realize it or not the OP's problem is a problem of organization. of which forecasting and hiring and firing and planning and marketing and selling are a part of his business.

Anyway I have wasted enough time talking to you.

To the OP that is my story and I'm sticking to it.

From contributor da

"I know they do not predict when my customers decide to retire, or when a competitor decides to give away their work, or when my electric company decides to increase rates. We do not do business on a national scale. There is no aspect of my business that I would change even with a 100% accurate 12 month economic forecast. I venture to guess most wood shops are in a similar situation. Not all. Most." Sure they do. -

You are full of it, and full of yourself. Good day.

From contributor pa

Apparently dave would also say that

actuarials would fit into this category, or maybe someone who looks into want ads for certain types of jobs going up or down would be an indicator, or building permits, or the baby boomers who would buy at certain ages, or international trade effecting certain types of jobs, or the impact of new laws, or or or

From contributor Ti

Gentlemen, this is getting comical. I won't even try to engage whatever debate seems to be going on.

I do appreciate all the experience and insight. I'll add it to my noggin as I contemplate the right move. I've conducted three phone interviews today. Two maybe promising but they all are at first. One was unbelievably bad "I can't get my scooter started so I'll have come in for an interview next week" LOL

I've been a business owner for 26 straight years now. So you all have touched on items I've contemplated and acted on at one time or another my business model is different than the next guys but basic strategic planning does apply. It is an organization problem, and often part of the problem is that you're just too close to it to see the solution. Voicing the problem helps. Reading the banter you guys post does help. I do know how to market myself and am in the process of working with a branding firm to help me understand what's important and what's not as far as promotion. We should all do that. How many have super expensive websites that are so busy, full of nonsense and hard to use that they are a deterrent? I'll alter the website as part of a strategic plan that makes sense. We actually do have professional photos of most of our work. Which I take as part a sales call. I simply at this point don't need more work. I'm fortunate that I have a nice network of designers and architects who specify my cabinets. I won't rest on that but I need to serve them currently. I just need to learn how to execute what I have better and sanely. Then decide if I want to grow. Which is why I posted originally. I'm still building the bones of a solid operation and need good employees. That's what I haven't figured out yet. I always approached it the other way, sell something and then find a way to get it done. In this business, I'm afraid I'm setting myself up for failure without the staffing.

From contributor Ca

Tim,

If you are working with Architects & Designers I would guess that a significant constraint for you is getting decisions or approvals. Another hang up is probably getting reliable job site data so you can go into engineering drawings.

These problems are compounded if you are trying to work for several customers simultaneously. You might be better off to work for fewer of these customers.....i.e., it might be easier to get 40% out of $250K rather than 20% out of $500K. You certainly will have an easier time of it if you only cherry pick the profitable jobs.

Think of this approach as a global batch size reduction.

From contributor Ke

Someone asked to define the cnc reason. I can take a school kid and in a few minutes they can make perfect parts. The original poster is trying to find or create skilled labor. If he can remove the need for skill = problem almost solved. He still has to find someone willing to show up and try.

From contributor Ca

Ken I agree. We put in a cnc router and the software. It's amazing. Even the skilled guys would misread and not cut items that are essential to the cases and we would have to make that up, stopping the assembly Now we are all truly amazed how that has gone away. Recently the cnc went down and we had to build with our old system. Oh it was painful. I'm looking for a used cnc router and bander to back up what we have. Adding redundancy to our system.

A single phase shopbot would be a great solution for the cutting even if a temporary solution, I'm sure it could cut very accurate parts repeatably. And, I'm sure cabpartspro would be a great buy along with vectric or some of the other programs that now can go to code from design and allow the office to push the shop a little more with just a few hours detailing vs days of engineering. You could never pay for the time savings the software/cnc gives you with employees, ever. You just cannot run the numbers and quantify the shake out. it never comes out. You just can't pay 20k a year or less over 4-5 years and get the same performance or output. (For a smaller 4x8 like a shopbot or shop saber etc ) Period

The best part of the whole cnc/software combo is the more talented guys are handling some of the things the we are not running on the cnc.

From contributor pa

Passing thought, dave indicated he had not heard of anyone predicting 9/11/2001.

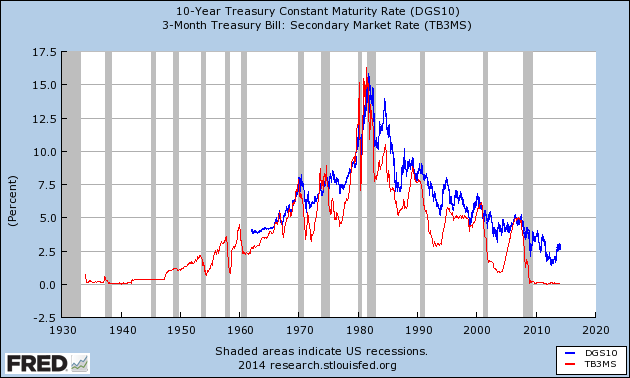

It turns out that it is a rather well known that you can predict a recession by looking at the bond market. When the 10yr treasuries have a lower yield than the 3 month treasuries there will be a recession in about 10 months.

If you look at the graph below it shows that the 10 yr treasuries were selling for less than 3 month treasuries towards the end of 2000. This indicated there would be a recession toward the end of the 2001. What is interesting is that the recession would have happened regardless of 9/11.

The graph also indicates the recession in 2007.

Not that dave will consider this but I thought it was interesting as yes people did predict 9/11, regarding that recession.

How does this pertain to the OP? Because this year is predicted to be flat. As Larry alluded to, however they also predict 2015 will be good. This year might be a good year to get organized?

In full disclosure I'm a student of this stuff and may very well be WRONG, in which case I will refund the price I charged you for this advise.

From contributor ca

Hey Pat

Speaking of predicting the future based on the past...... I stumbled upon the realization the going from screen and 72 pages of shop drawings to machine (cnc router) could produce different results. Just a thought.

cm

From contributor pa

Is your gibberish worth asking about?

From contributor ca

the gibberish is...... you spend a couple days drawing a job for a customer to review on paper, (Or in our case a couple of weeks on a school job), wouldn't it be great to send all that field verified info to a machine that can cut a lot of the parts ?

From contributor pa

Yup but if you don't get the job then your overhead eats you up.

From contributor ca

Why, oh why, are you executing shop drawings without a contract or purchase order ?

From contributor Ch

"Why, oh why, are you executing shop drawings without a contract or purchase order ?"

That is the same question I have. I do not start on any shop design (I call it the "engineering design phase") until I have a signed agreement AND a check.

Then, the necessary drawings, CAD files, etc. are completed in the office. Outsourced items with long lead times are ordered. Other materials are ordered for JIT (Just In Time) delivery when appropriate.

I have a CNC, so when the plywood arrives it takes it turn being processed, then banded, then off to the finishing area for sanding and finishing. Except for the crown moulding, valet rods (for wardrobe closets), and a few odd things, NOTHING requires a tape measure. What does need measuring gets done in metric; specifically mm. (I avoid cm completely.)

After finishing, assembly is accomplished (we flat finish), again without any tape measures (except for the few items mentioned above).

Having a CNC is more than just having an "employee" that is willing to do highly repetitive work, doesn't take breaks, doesn't call in sick, doesn't complain about his personal life, etc. It is a mindset. Before any job goes onto the shop floor, everything is planned out ahead of time. All of the measurements are handled. All of the doors, drawer fronts, drawer boxes, slides, pulls, hinges, colors, finishing materials, fasteners, trim, etc. are all defined up front. This makes production much faster, more reliable, and easier to manage.

Does every job fit into this category of CNC thinking? No, of course not. But, in my shop, about 90% does. And, we do custom sizes, configurations, shapes, and more all of the time. Need an L-shaped bookcase box? No problem. There is one defined in the computer. Just tell the computer the dimensions, and it will produce the correct part diagrams for the CNC. The software will produce a layout pattern (optimized, nested) for the sheets of plywood. The operator just needs to load and go. Absolutely no measuring.

Do I think a small shop needs a CNC? That is a business decision the owner needs to make. In my shop, I decided to purchase a CNC years ago and have not regretted it one bit. It simply doesn't "forget" to drill the correct holes, or measure wrong and cut the piece too short. The front office is the key. That's my job to input the information correctly. I don't even want to think about running my shop without a CNC.

Now, if I could only automate my finishing department... :-)

From contributor Ti

You know. I don't give a rip about the economy. That's not to say I don't pay attention to trends but I firmly believe those who are paying attention will always find a way to make money and position themselves to be ahead of the competition regardless. Each market is different and if you are paying attention you don't need to rely on economists to predict your future, you can see it coming, remain diversified, and see shifting segments. I cannot stand it when people complain about their situation "due to the economy" That's their fault. Anyone who didn't see the bust in 08 coming was ignorant. My lessoned learned was that I was lulled into complacency, and and too much debt. Nearly took me out. I'm still recovering. From that time forward, I'm dedicated to not incurring new debt. If it's in our shop it's paid for period. I know that limits me at times but I can sleep at night, I always know where I stand, and if it simply isn't working anymore I'll just shut it down. I don't need to be convinced to buy a cnc and I get that even if I borrowed the money I'd likely be money ahead but it's against my business plan. I'll struggle and save and add the equipment. Never in my life have I been sorry I've added a quality tool. First quality saws, then an edgebander, then line and hinge boring machines, finally high end paint pumps and a large finish room with a quality paint booth, sealed conditioned curing room, and separate sanding room with dust control.

Having a process is critical. Same way every time. I don't even need to think about measurements when I cut a job out excluding special cabs. I'm with you on the finish room. It's a process as much as possible but it's still an art and learned skill. It's likely also the most important part of my product. What sucks about finish is that it is continually changing! Popular finishes, products etc.

From contributor pa

Do you see the next 2008? I guarantee you will give a rip when it happens...

IMO you are going to shrink willy nilly...

From contributor Ti

Thanks Pat, I think you're too involved in your books and charts to spend time thinking about what I was saying.

No reason for me to go on further but thanks for the encouragement and levity to this discussion.

From contributor De

What Ken and Cabinetmaker said about cnc is right on!

A cnc is the best employee you will ever have. You send it a file and push the button and it makes you parts. It doesn't show up hung over, it doesn't have a girlfriend, won't piss and moan about working overtime, doesn't cut parts with wrong grain orientationetc, etc.

I used to have 3 guys in the shop screwing up stuff on a daily basis doing $800k a year. I switched to nested base and have one guy in the shop and we did $1.3 last year.

Yes, they have a learning curve and yes they require an investment, just like an employee does.

From contributor Ma

I have owned my shop 14 years. Unique high-quality custom niche product. Had 5-6 employees working full time until just a few months ago. We had increasing sales every year we were in business until just this year. (Got divorced 2 years ago and ex has constantly hassled me with lawyers & courts so I didn't have near as much time to dedicate torwads promoting business.) So reduced 5 months ago to just 1 employee and 2 months ago reduced to just myself.

Honestly it has been such a nice experience it really makes me wonder if I ever want to grow back to having more employees. When I had employees we were able to bust out large amounts of production quickly, however for me it was very stressful and difficult managings all the clients/projects/employees etc. Employees got-r-dun but they also brought a lot of drama between the ones that didn't like each other and lots of other issues with everybody. Some materials & tools got stolen - probably scrapped/pawned for drugs. Our niche work does have a lot of peaks and valleys with sales. Profit during the peak times was just fine, however during slower times it seemed I spent most of my effort trying to round up work to keep the employees employeed while basically working for free myself until the bigger projects came back in. Anyway, now that I am just a 1-man shop again I am only choosing the projects that are most desirable. No longer chasing any 'filler' work for the employees. No more drama between workers, no more theft. Also save a lot of time converting the project details that are floating in my head to the workers. I am also doing hands-on fabrication again, something I haven't personally done for about 7 or 8 years as I was always bringing in business while the employees did all fabrication. I am really enjoying the hands-on work. When I first started my business, I did all the work myself, however that was my 'starving-artist' days while I struggled to learn my craft, dealt with cheap or improper equipment while we slowly upgraded to what was really needed. As employees were brought into my business machinery and processes were upgraded to be smoother, but by this point I was rarely hands-on -- my employees were the ones using the very nice new machines. So now that I am doing the hands-on work again, it is a pure joy to work with the best tools, optimized workspaces, and improved processes. Without maintaining payroll anymore, I am actually making more money in much less time, in a much more enjoyable & relaxing environment. My shop buildings are on my homestead rural property, have house, fishing ponds, shady trees, etc. Relaxing place to just putter away on our artwork. Really makes me think hard about growing back into the employee game. I really enjoy the craftsmanship more than I enjoy managing a workforce. Because sales are currently slower volume I have been spending a lot of time working on making the processes even easier to do, especially geared around a 1-man process. Some of our steps involved man-handling larger materials into place -- which was easy when had 4 guys there at once, but with some time & brainpower invested into making material handling jig it is now possible to do same step with 1 person in a much more controlled and safer manner. So even if I do end up need help again, I could hire 1 employee to be much more effecient compared to how they were before. However, I am leaning towards investing more into automation machinery rather than employees. Cost of a few 1-year salaries can buy a pretty good amount of machinery automation, without the drama or unreliability, plus the machine can continue to work year after year.

From contributor Ti

Ok, let's go down this CNC path for a minute. I understand the costing business side of the CNC investment completely.

I'm at the point after phone interviewing nearly 50, hiring 3 (subsequently let go for various reasons) and thinking there were 3 others that were interesting who never showed up and still no employee. That I am going to take the CNC look very seriously.

Where do I begin researching CNC and what do I need? The more I read and look online the more confused I become. I need a machine do make Euro box parts. Not doors or drawers. I need it to be well made but perhaps not the latest and greatest. What are the important criteria ?

From contributor Ch

Here are a couple of ideas, in no particular order. I have basically an entry level machine (2004 shopbot PRT 5x10 table with a router acting as a spindle).

I like the 5x10 table instead of a 4x8. Occasionally I have used 5xSomething sheets. Also, I have machined some solid wood that is longer than 8'. The latter does not happen too often, but it is nice.

I would suggest you visit the IWF show in Atlanta this summer and watch the machines in operation. Of course, the sales guys are going to demo what their machine does best. But, you will learn a lot by just watching and asking questions.

I would like an Automatic Tool Changer. It was out of my budget when I bought the machine. In fact, I don't believe they were even offering that option back in 04 for my machine. So, I am the "tool changer" for my CNC. I have managed to design my frameless boxes so I only use two different bits. And some sheets only require on bit. It adds a minute or two to each sheet, but my machine isn't the fastest to start with. And, my shop budget has other priorities as the business is growing this year.

I like the fact that I can screw parts down onto my spoilboard. It is replaceable. I use 3/4" MDF and resurface as needed. When it gets too thin, it gets replaced with a new 5x10 sheet of MDF. I do not have vacuum hold-down, so screwing the sheets to the spoilboard, then machining parts in the correct order so they don't slide around is necessary. A vacuum hold-down would eliminate a lot of these issues. But, some small parts may still float around even with vacuum unless you have a specific hold-down jig. For most euro box parts, the vacuum hold-down should be fine.

Check into power requirements. My equipment is single-phase. Spindles and vacuum pumps may come in single or three-phase. Does you building have adequate power?

You will need good dust collection on the CNC while the parts are being machined. See what is required for each machine.

How much floor space is required? You need room around the CNC for safety, room for the gantry to move (unless it is a moving table style), and room for loading and unloading. Think about traffic flow and material handling. Will you use a forklift? If so, is there enough room? I do not have a forklift, but use a flip-cart from Hafele to load sheets. I can handle loading by myself this way.

Another issue is software. Can you get the sales guys to make parts that you will use in your business? Not just the pretty demo that they have carefully designed to showcase their CNC.

Speed is an issue, but so is accuracy. I would venture to guess that most CNC's nowadays are quite accurate. Speed is relative. Think about your entire project. If it takes 3 hours to build a box from scratch without a CNC, and adding a CNC reduces that to 2 hours, that is probably a win for your business. If you spend 5 times as much money on a slightly faster CNC to reduce the overall build time to 1:58, that 2 minute savings is probably a waste of your money. CNC is just one part of the overall picture.

Support from the manufacturer is very important. Will they have replacement parts when you need them? Will they help with answering questions, both when you get started and later down the road? Any machine is worthless if you can't use it.

Support from the software company is very important. Get a demo version of the software before you buy so you can try it first hand.

Having the CNC manufacturer and the software company work together instead of pointing fingers at each other when there is a problem, is very important.

Talk to other users of the same CNC. Right! You are already starting to do that. :-)

Try to visit some actual CNC users' shops and watch the machines in action in the real world.

Best of luck. Take your time.

From contributor ca

Charles,

It takes 35 minutes to cut a three drawer base cabinet, install the slides and assemble the box. We do all of our cut out on an altendorf slide saw.

The cabinet parts are screwed together. The box material is 3/4 prefinished plywood with 1/2 inch backs.

How long would these operations take to do with your CNC approach?

From contributor Ti

I can argue this many different ways. I'm not in as good of practice as I used to be but I can still cut (traditional table saw), edge band, dado, line bore an entire kitchen in one fairly easy day. Not assembled as I send it to paint first then assemble. The problem here is it takes complete understanding of what you're building and all the little idiosyncrasies that cabinets can have. This takes a certain level of skill and thought. So in an effort to stay on track since I struggle to get that kind of help, I'm considering hiring lesser skilled and let the cnc programing sort that out. It doesn't completely solve the problem but it will save some headaches. Such as an employee changes table saw blades and not adjusting the fence scale. All of our cabinets were a 1/16th too large. That's a problem, or indexing the line boring from the various ends during production.

All that said, all I'm interested in now is how do I educate myself properly about which CNC will meet my needs. I don't know what's important and what's not.

From contributor De

Tim, your on the right track with that kind of thinking. I'll share a few things, feel free to pm me and I'll give you my phone if you want to ask me questions.

The most important part of the cnc is to understand that you have the physical machine and the software. You want a softwareackage that will take you screen to machine. They range from free to an arm and a leg. Thermwood is free but only works on thermwood machine, Mozaik, Cabinet Vision and others are available and well suited to cabinet production. I have cv and can design and out put to the machine direct. Call these companies and get a demo from the reps. Remember they are sales guys and are biased to there product.

There are lots of equipment companies. Naturally, you have to get what you can afford, but get all you can afford. Auto tool change capability is a must. You can do without a drill block but I wouldn't get one without it. I wish I had a bigger block as we have all kinds of bits in ours besides the 5mm.

Multicam, Freedom cnc, Biesse, Thermwood and many other have reps and other resources. Give them a call and ask them to educate you on their equipment. Used is always an option but you have to be careful. I wouldn't buy anything that I didn't know was an up and running machine, because you can eat up your savings pretty quick with a tech onsite for a couple of days and a few big item parts.

From contributor La

I pretty much agree with Derrek & can sure see Mathew's point also. As for a CNC A lot depends on your expected out put. Size?? 5x10's are common but if you start doing commercial work you'll wish it was 5x12. Spindle hp, not a big issue for cutting melamine, plywood etc. Tool changer for sure, Drill box, yes with as many spindles as you can get. Speed, there is a lot of BS about this. To a great extent it is governed by the tooling and cut quality and super fast doesn't get you a lot more work out the door. For kitchen work, nested with a good sized pump is the way to go. I've seen machines that don't have locating pins, bad idea! The machines that have push off, pull on and bed cleaning are significant time savers but may be over kill for you at this time. There is more to being a good CNC operator than just pushing the green button. Needs to think!

See you @ IWF.

From contributor Ch

cabmaker,

I haven't made a 3-drawer base cabinet in a very long time. I also have an older, slower CNC with no tool changer and no vacuum hold-down. I know there are machines that can process a sheet of parts in about 5 minutes, where the same complex parts might take mine 30. Different tools equals different results. So, timing comparisons are not going to be worth much. I am guessing that with my set up it would take more than the 35 minutes. I would drop a sheet of plywood on the CNC table, fasten it down, the run the program. Then, I would band the parts and send it to the finishing department. There it would take some time. But, let's assume I could use pre-finished stock. The parts would go straight to assembly, add the slides, and assemble. Only two machines have been used: CNC and edgebander. No secondary processing of the parts is needed. That is, all hole drilling was already completed by the CNC.

What is important to me is reliability, accuracy, and capability. I can start the CNC, then walk away to do something else. I know the machine is going to get the job done correctly and accurately. All of the holes, including specially located holes for atypical hardware, will be in the exact locations. This saves a lot of time and avoids a lot of mistakes during assembly. Regarding capability, I have a number of parts that have curved (both inner and outer) profiles. These parts must be milled extremely accurately or the final product simply will not function. My CNC, although slower than some others, will do this flawlessly every time. For me, this is a competitive advantage in my business.

The CNC is reliable. It doesn't take days off (well, usually. Occasionally it does require maintenance.) It doesn't need to take a lunch break (I eat my lunch while the machine is processing parts.) It doesn't ask for a raise (occasional software upgrades do happen, but not often). It doesn't get tired near the end of the day or week and start making mistakes.

So, it is not always about timing for my particular situation. Would I like a faster machine? Oh, yeah. Would the ROI be worthwhile? Maybe, but probably not at my volume level right now. My CNC may only run one or two days per week. The majority of the project time is spent in the finishing department. (Sorry, pre-finished plywood is not applicable for my product line. It would be great if it was, but it isn't.) So, decreasing the CNC time, even cutting it into quarters, would not have a significant impact on the total time. The constraint is the finishing department. But, that is another topic completely.

For your business, CNC may or may not be the correct answer. I am not trying to convince the world that a CNC is the only way to do things. Or, that it is the best way to do things. I can only relay what I have learned from my experiences, and what I know about some other businesses from their experiences. I can talk about what works for me, and what is important for my business. If this information helps others, then great. I am happy to help. If it doesn't apply, then please feel free to disregard it. It won't hurt my feelings a bit. This is a business decision that we each need to make.

From contributor Ti

Thanks guys, the input is appreciated. I can see the argument regarding speed on both sides. I tend to see that my application is more in line with Charles in this case. Our fabrication time, while it makes us money isn't my main concern it's cabinet system accuracy. If I, my finisher, or his helper can load plywood and continue other tasks and have mistakes that's most important for me at this point.

The point remains where do I look and what am I looking for?

So much out there, but it is all foreign to me. I'm very computer literate and my son is a programmer so I'm sure I can figure it all out but I still need a system that's easy to use. And I have zero idea about what hard parts are important.