Software and Learning Curves for CNC Carving

Finding the carving software is the easy part. Understanding its power and its limitations takes time. January 25, 2013

Question

I'm seeking software to carve a profile from an astragal on a door. We have been asked to replicate the door. I thought I would try this on our CNC. We have a Biesse and use Biesse Works. Any thoughts from shops that use software on their CNC to carve? What is the learning curve?

Click here for higher quality, full size image

Forum Responses

(CNC Forum)

From contributor I:

Check out Vcarve or Aspire from Vetric.

From contributor D:

I looked at the photo imported to Aspire, modeled it and toolpathed in 25 minutes. Learning curve is pretty easy and the Vetric forum rocks. If you don't want to do it yourself, sub out the file to Vector Art 3D. They did this one for me when I first got started.

Click here for higher quality, full size image

From contributor W:

I use Aspire to program and cut on my Biesse Rover. Biesseworks will not be used to produce this.

From contributor T:

Ditto what contributor W said. Biesseworks only lets you do 2D work. Your pic indicates you need 3D modeling. Aspire (by Vectric) will allow you to do that.

From contributor U:

I'm in the same situation. I have a Shoda router and use Router-cim. I'm looking for something easier to program 3-D carving. What is the cost of Vectric? What's the difference between Vectric and Aspire? If I wanted to farm out the programming to Vectric, can they generate a ready to use program with my post processor?

From contributor K:

Post the toolpath preview image created by Aspire. I would like to see how close it is to the jpeg image.

From contributor J:

After all the posts I have participated in on WOODWEB about carving and its enhancement of our businesses, I gotta say some of you have a pretty good grip on it!

Click here for higher quality, full size image

From contributor K:

Contributor J, can you create an accurate enough model in Aspire from contributor D's image to reproduce that molding? I am playing with the trial and I couldn't get anywhere close. I would think you would need to scan with something like Polhemus to recreate that molding close enough.

From contributor N:

Contributor D, that's really impressive if you can go from that pic to toolpath in 25 minutes. My experience with Artcam and Alphacam is, when a photo like that is scanned, the lightsource of the photo must be straight on. In this one, the light is from above and the shadow created will not give you an accurate model. Yeah, I can get a model in 5 minutes in Alphacam. Something worth running is another story.

From contributor J:

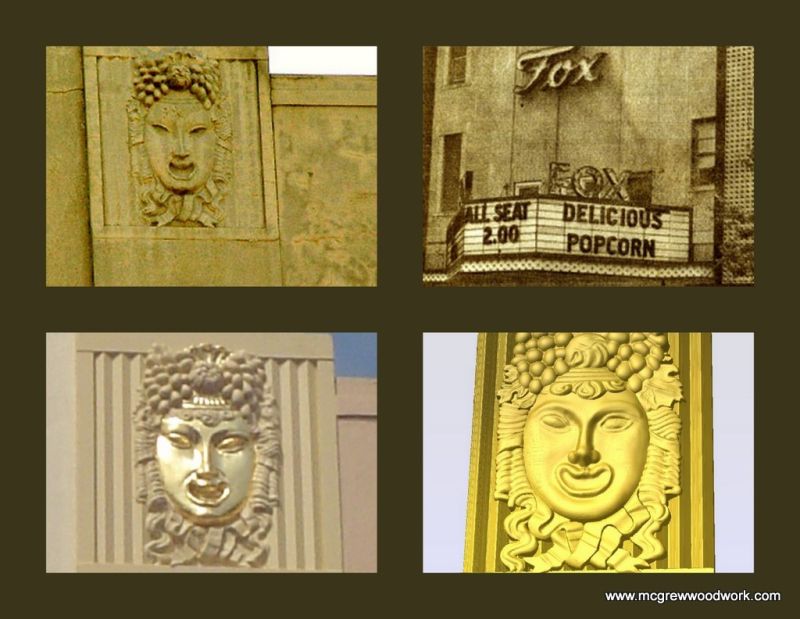

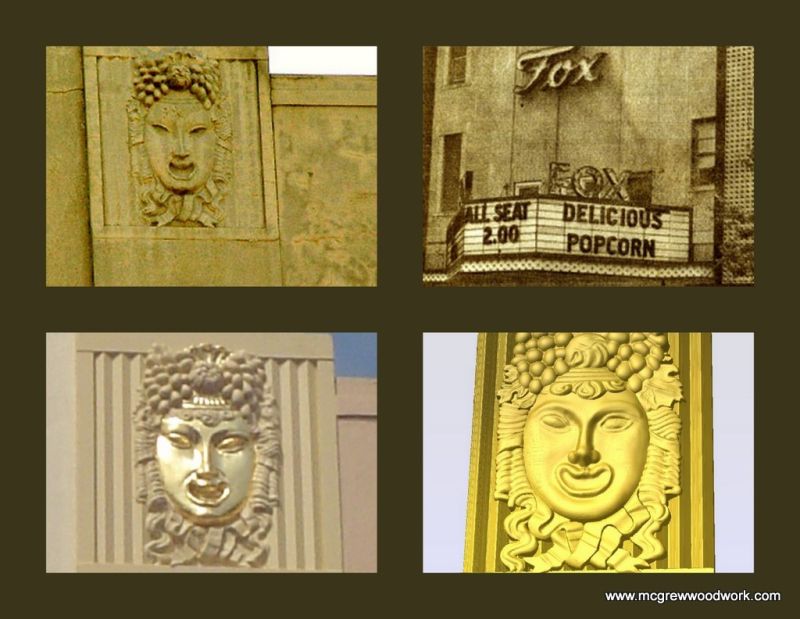

Absolutely on replication, to many import it and try to use the bitmap to 3d feature this has a purpose yet we use the bitmap as the guide, then create the components and bring them together. Below are photos of the newly renovated (old FOX) Nickelodeon theater in Columbia SC. It is a large part of our downtown revival and I chose to donate all millwork and then some to accomplish the project. After the old thick paint was removed from the exterior, they found the mask carved into the facade from the original construction of the theater. I got the picture and we modeled it into a 3d copy so we can use it for a large wall decoration (and fundraising pins). We saved the theater a lot of money. We got lots of requests for work in the surrounding buildings. Give a little - it does pay off!

Click here for higher quality, full size image

Click here for higher quality, full size image

From contributor D:

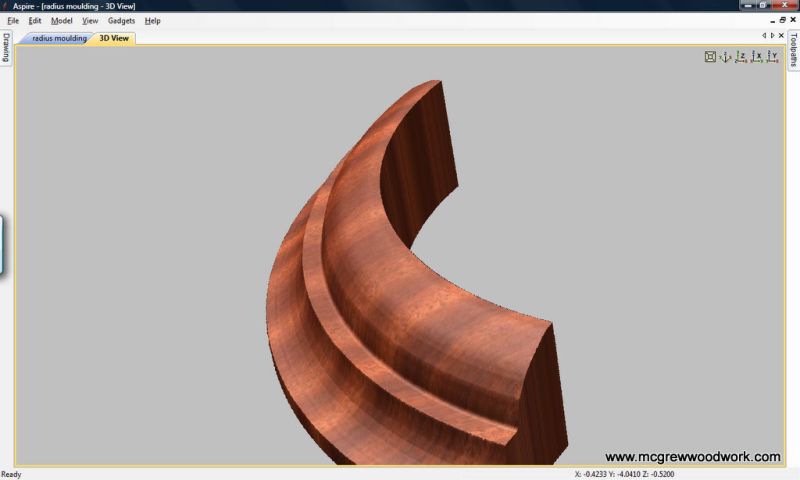

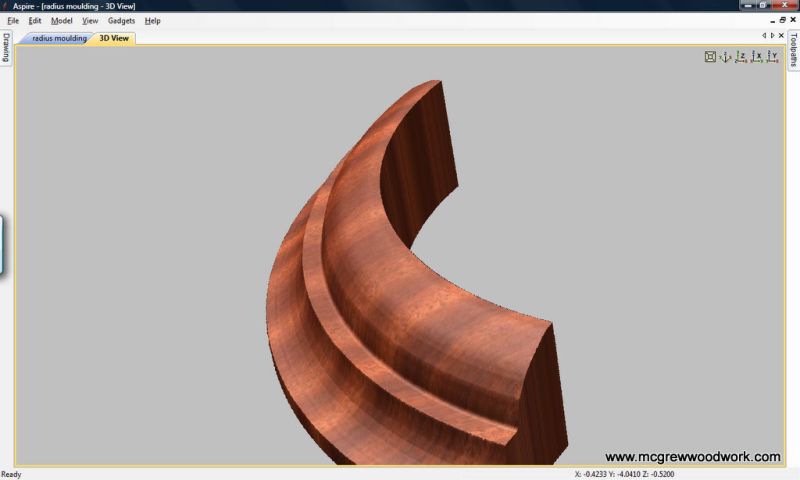

My model is nowhere near an exact replica. Yes, the image has to be taken from straight on. I do not use the fit vectors to bit map option in aspire that often unless the picture is clear and one or two colors. I use the draw poly line and freehand the best that I can and then sculpt as needed. This model starts out as a two rail sweep and the detail is merged. I will post after I clean it up.

Okay - busted! Not ready to machine in 25 minutes, but close. Vetric makes ASPIRE.

From contributor K:

Thanks for the response. I would think it would be hard to get all the nuances of a carved piece just from a picture. It will be great to see just how close Aspire can get. Scanning still seems to be the best option.

The biggest problem with something like this is to get the customer to pay for it. If it could be done in 25 minutes is one thing, but I would bet this turns into hours to get from the picture to the machined product. I need to go through the Aspire tutorials. It would still be fun to do some of this stuff.

From contributor N:

A while back there was a post about someone wanting to engrave a simple graphic and text, either burnt with a laser or cut with a router. I remember saying I could program that in 5 minutes, which I could. This is different. I strongly disagree with influential statements on here that could lead to great disappointment if a certain investment in software isn't the magic they're led to believe it is. The fact is, you'll need skills like the ability to measure 3d objects and determine where you can use profiled cutters in one pass instead of going back and forth with a ball end bit all day, and still end up hand sanding. Grain orientation affects your attack angles just as if you had a hand chisel in your hand - metal and plastic are way easier. It also is insulting when the hand carver crowd dismisses these skills as if I were simply pushing a "copy" button on a Xerox machine. Getting into carving wood with a CNC takes a leap of faith and a lot of dedication. Expect to make mistakes along the way, because there's a learning curve just like anything else.

From contributor J:

This church was done in Aspire for me, might have taken a bit more than 25 minutes. The crown I did. I can understand this is more difficult for some than others. I outsource a lot of my files to others with the program and can correct, change, manipulate size, etc. when I need. Over the years I have gotten better. A file like what was shown can cost $45-70 to get prepared, yet he will own it on completion. I have done plenty of this. At this point I have some 4000 files. I would not discount Aspire and its advantages. It is a learning curve, yet learning not to cut my fingers was also! This is our church in Ridgeway, SC I did for a departing vicar. Cost 200.00; value is priceless.

Click here for higher quality, full size image

Click here for higher quality, full size image

From contributor K:

The curved crown you show I would just draw in eCabinet Systems software and let the Thermwood model it. I do quite a bit of restoration work and it would be nice to be able to match carved moldings, but in most cases I would have to give this service away.

From the original questioner:

Thanks for all the information. It occurred to me that I am going to have to outsource the carving to a hand carver or a person that can create a 3D image of the carvings. If I decide to have a 3D image made, I will then have to purchase software (let's say Vectric or Artcam) to take the 3D image and apply toolpaths to it - is this correct? Then that same software will also be able to run the part on the Biesse - is this correct? I have attached a couple other photos of the door. I believe I am going to purchase the capital at Enkeboll that resembles this one.

Click here for higher quality, full size image

Click here for higher quality, full size image

From contributor J:

I have a similar file for the capitol, yet I will say there are some better purchased. The Enkebol capitol is one, yet most all of my flat 3D work I do. I have a CNC lathe on my machine, but for glueup file production and machining when I only need a few, often I purchase them. You will have to have a program that will machine it.

Click here for higher quality, full size image

Click here for higher quality, full size image

Click here for higher quality, full size image

From contributor N:

Yes, definitely more complex now. I would guess not even a laser scanned 3D model is the answer. With all the undercuts on that, I'd make the top tripod shaped piece separate, by hand, with bandsawn 12/4 stock. Then route around it with various bearing guided bead and cove bits. The leafy portion is way tougher - either you'll need a 4th axis lathe CNC, or you split that on the screen, say, maybe in three pie pieces to be machined separately, then glue them together afterward. The bigger photo is more informative than your first one. The astragal looks like you could just put up a blank and make the little swoop cuts only on the CNC, then round it over and flute it on the (manual) router table. The bottom rail decoration doesn't need any carving software. I'm sure I could draw those lumps out in Alphacam and merely apply a 1/4 or 3/8 bead point router bit on those lines and match that pretty close. In any case, this is a big undertaking, probably closer to 25 hours, not minutes.

From the original questioner:

Contributor J, nice capitols.

If I get into carving on a CNC, do I use Vectric software to machine parts as well, or is Vectric only used to make a 3D image? Or do I have to purchase a CAM package to run tool paths and make the part? Can you write down the basic steps of what it takes to make a carving on a CNC? I am still not sure what it involves.

1.) Take picture of part?

2.) Download into Aspire?

3.) Manipulate image where it does not look the best?

4.) Assign a toolpath?

5.) Assign tooling?

6.) Run?

From contributor J:

Vectric is the cam engine and will make code. Go to the Vectric website, download the demo for CarvePro, go through the tutorials, then run a test file on your machine. Before you spend a dime. I purchased the Capitol file from others. There is a learning curve. Do not go down this road with work waiting on it - it will mess up your success.