Question

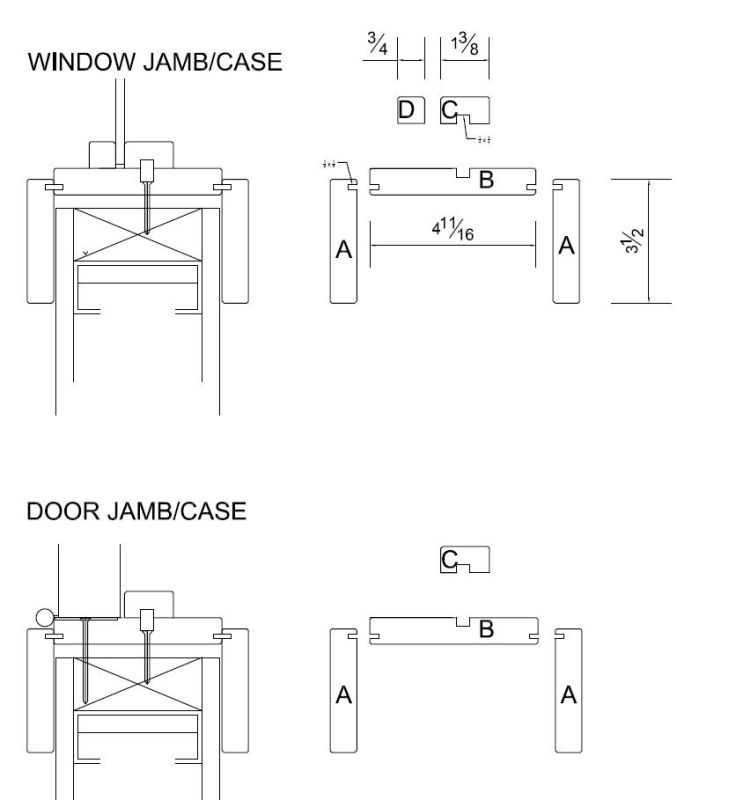

I am completing a commercial job which includes several man doors and inter office windows - all stain grade maple. I came up with the attached profile which I thought might work well for several reasons. I do not have a moulder, just a shaper and I think the economics work for someone else to surface and profile my stock over doing it in house. The bigger aspect for me is to limit the site work. The spline will make for consistent reveals, the add on door/window stop will hide the install screws and I can use the same profile for windows and doors for the most part. I may even go so far as to case one side of each jamb in the shop.

I also thought about using GRK shim screws for the actual install. Probably shim the hinge side solid and use the GRK's on the opposite side to tweak the reveal between the door and jamb. They look like a neat idea. Has anyone tried them out there?

Forum Responses

(Architectural Woodworking Forum)

From contributor M:

The spline I think will give you fits unless you are trying to use no fasteners. The problem being in a real world application is that the door is probably not perfect, you won't cut your miters perfect, the walls aren't perfect, drywall is not perfect, etc. If it was me, backouts on the moulding, shim and nail the jambs behind the stop accordingly, nail on the casing, and call it good.

A good fit to walls and jambs takes some finesse, and locked into splines or pre-nailed trim doesn't afford you that luxury. Achieving that good fit may mean you have to roll the casing a little and alter the degree of your miters, or you may actually have to plane a little of the back of the moulding to get it to sit good (reason for backout) to the wall.

If you have decent carpentry skills, holding reveals both in the door hanging and casing should not be difficult, and doesn't require fancy screws or overkill joinery. Also you may want to get a price from a millwork shop, your time is money also.

I like the idea of relieving the back of the casing so there is less material to remove should some finessing be required. I am oversizing the jamb 1/16 or so to permit some drywall deviation but I hear what you are saying about what one inherits in that department. I will bring a 26oz drywall tenderizer either way.