Pricing, Productivity, and Profit

An inexperienced cabinetmaker asks for help ball-parking a project, and kicks off an interesting discussion about how long it should take to do stuff. February 27, 2015

Question (WOODWEB Member) :

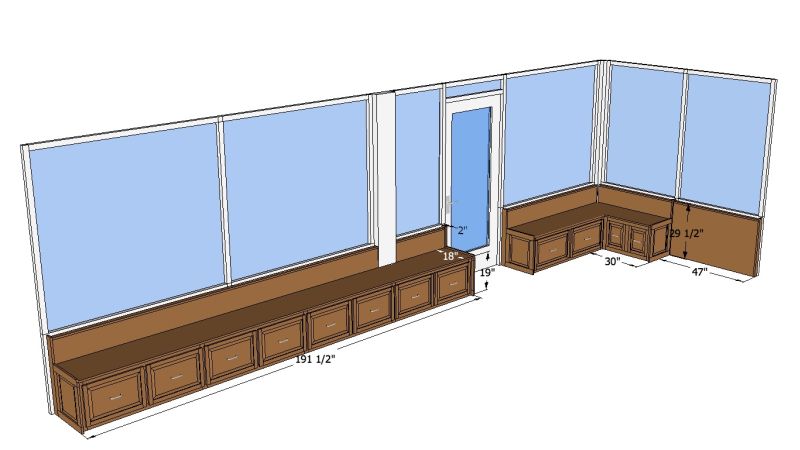

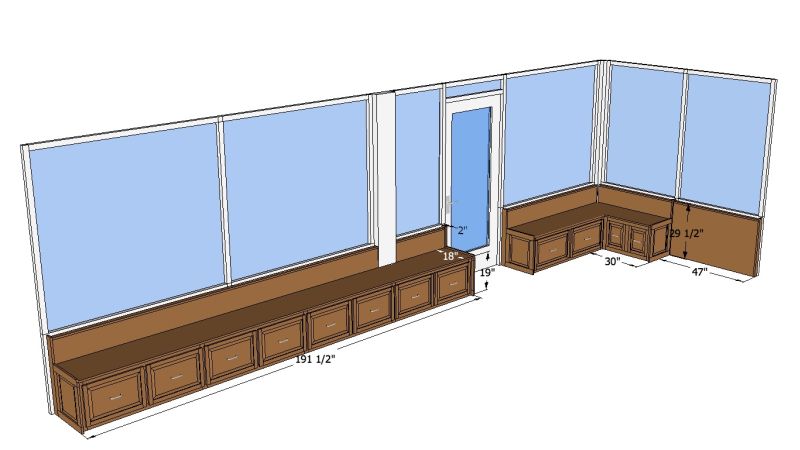

I just started doing this professionally about a year ago, and I still am unsure of what a fair charge is for a piece of work. Here is a bench seat a couple wants for their sun room. There are 12 deep drawers, and the finish is to match the other woodwork in the house, which is stained maple. My numbers add up to $6200 - am I in the ball park of what you would charge? The dark brown is what I would build.

Click here for higher quality, full size image

Forum Responses

(Cabinetmaking Forum)

From contributor M:

A couple thousand high for my market, but could be right in line with yours. As always there are many variables here.

From contributor L:

A lot of variables but you are in the ball park.

From contributor Y:

I'm with Contributor F but I'm also in the Midwest. On the East Coast or West Coast you're probably right on.

From the original questioner:

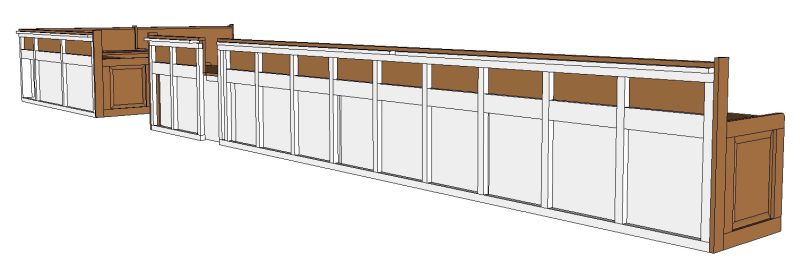

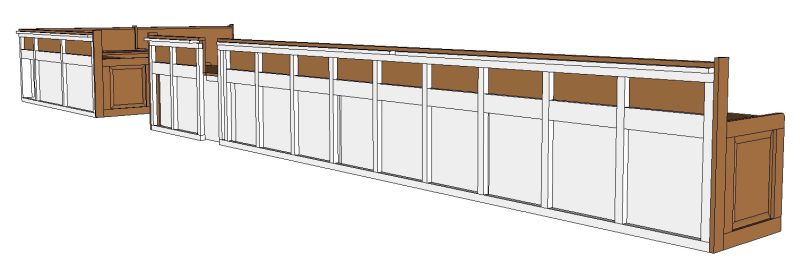

Thanks. I've priced the drawers (boxes and fronts) from outside resources; the boxes made of dovetailed 1/2" baltic birch, assembled and finished. These drawer boxes are 14" high x 16" deep. From three sources, the average comes to $700 (btw, that breaks down to about two cents a cubic inch; and I found that drawer boxes that were 4" high were about four cents a cubic inch). Fronts for the drawers averaged $500. Add in shipping, the cost comes to about $1600. Then there's the cost for hardware and finishing, so in the end, the drawers alone for this project cost about $2000. Another way for me to have a reality check here is how many hours would a project like this take you? Also, the back side has to be built up for support as shown in this additional drawing. The current wall is just a sheet of exterior siding, and the owners want that area behind the bench insulated.

Click here for higher quality, full size image

From contributor C:

Your second question is better framed than your first one. How many hours it should take will generate more useful answers than how many dollars it should cost. It will always have to cost more in New York City than the hinterlands of Oklahoma. Something also to consider is what exactly is important to the customer? I would guess they care more about what it looks like than how it operates. Out of a dozen drawers like that only a couple will ever get opened more than once in their career. There are probably a lot less expensive ways to produce these drawers than you have in mind. If I was proposing this job I would discuss ranges in budgets and specifically ask them what is important rather than assume what is important.

From contributor G:

You are going to make 12 large drawer fronts, 12 drawers, 4 end panels, 23 feet of cabinets and seat, 27' of simple wainscot and chair rail, put in all the hardware, stain and finish all the wood clear on the inside and custom color match on the outside. And you are going to do this in two days? Is this by yourself, or a number of workers? Or are you outsourcing everything and just assembling the units?

From contributor Z:

Easily! If I had a big shop with dedicated shapers I could do it in one (plus waiting time on stain and finish drying). It takes motivation, not standing around wishing you were somewhere else.

From contributor M:

No, you could not do this is one or two days, even if you did it shoddy. There is easily a day of milling parts and a day of sanding, not to mention assembly, finish and hardware, probably a full day of installation as well. If I had a 100,000 square foot shop and 5,000 elves, I could do it in two days!

From contributor Z:

The most time consuming part is gluing up the raised panels, cutting to final size, sanding flat and machining. I decide what I'm going to get done in a day and do it. Sometimes things don't go as planned so it will take 12 hours, but the work has to be done. Don't be defeated before you start.

From contributor Z:

Let's talk materials. I would have $1485 in materials. Baltic birch drawer sides (not dovetailed). If I were dovetailing I would use soft maple for the drawer sides and 1/2" maple melamine for the bottoms. Dovetailing plywood is like painting your attic, what's the point?

From contributor P:

Your ratios are what I would expect to see from a framer. In other words they will figure material and their labor will be about equal to that so if you have a $100 in material the labor will be $100. They have to handle a piece of material one time. Cabinet parts have to be handled many times. On efficient production type jobs I have found the material to be equal to the labor, but you still have to add in overhead and profit. I shoot for a 40% gross profit (before taking out overhead). If the material is 1485 the labor might be 1485 if you are efficient. So I would price it at 2970/.6=4950. Since it is custom you are not going to be efficient at the job. So I would adjust it up from there. When estimating jobs one has have a unit of measure. Lineal feet is a lousy unit of measure. I would look at it on how long it takes to build a box, a drawer, wainscot by the piece (not square feet), tops, finish, install. This will get you a more accurate time estimation.

From contributor Z:

I agree with just about everything you said Contributor P. My pricing is not quite that simple, maybe it should be? You cannot expect 100% from employees or even yourself for long periods. I can't understand the times allotted for getting things done. Sheet goods take an average of six minutes each to cut on a tablesaw. That's a Powermatic with a Beismeir fence, faster than a slider.

From contributor P:

"Sheet goods take an average of six minutes each to cut on a table saw." I use to figure about 15 minutes a sheet on a slider. Six minutes sounds fast? There are a lot of little operations that have to be done on a part. On assembly if you don't have screw holes drilled by a CNC you have to layout location or make a jig or whatever but it takes more time. Let alone if it is canted curved something or other, assembly can take a lot of time. That is why I think that the unit of measure is important. How much time does it take to build a box? You can do the stop watch thing but you have to include transportation of material from one end of the shop to the other in there somewhere (this one may surprise you). Anyway you need to determine the time for a unit, a box, a drawer front, a eight piece of wainscot. Then add in final assembly, finishing, install, ordering material, drawings (one hour on drawings saves two hours in the shop), or anything else that applies directly to the job, before you say the times don't make sense. Another aspect to this is what the market price is, in other words what will people pay for your product? If it is in Hollywood, or Hawaii or San Jose or Manhattan they will pay more, more than the increased cost created by these areas.

From contributor Z:

Look guys, we all do our best with the circumstances we are in. I retired five years ago but have this uncontrollable urge to be productive so I opened a small shop. In the big shop I had a CNC Dovetailer, CNC Router and two Voorwood CNC Shaper Sanders and a 3 head 52" wide belt. When the router was on order I timed myself cutting the sheet goods on a job and it was six minutes per sheet average. I just wanted to see if this thing was going to pay for itself. The same was true of the slider, it was great for squaring up panels and stuff but you are moving a lot of weight with the slide and if you are going fast it will wear you down. The router took an average of six minutes per sheet also but it routed dados, drilled shelf peg holes, pilot holes for drawer slide rear brackets and lazy Susans, etc. and it can keep up that pace all week long, which a worker would quit if that was expected of him. I now use shelf standards, no dados and measure or jigs for the rest. I still have the Cabinet Vision program that gives me 100% accurate cut list and tells me exactly how much and what materials I will need and assembly sheets that show how each cabinet is assembled. No one chimes in on my side because those guys are probably working.

From Contributor O:

I have recorded production time in man hours as accurately as possible for the better part of a long career. I can predict pretty darn close what it takes to make most things. With experienced and skilled workers I do see their production vary by as much as 30% from one guy to another, so it is true that some folks are just faster than others.

From the original questioner:

I think from what I've gleaned from this discussion is my pricing is about right for this area (Austin, TX).

From contributor Y:

To the original questioner: Good luck with your project. If you can provide a quality product don't be afraid to keep your prices on the higher side.

From Contributor A:

Here in the Mid Atlantic I donít think I could do that job in house for the price quoted, but with subbing out boxes, fronts, and panels it may be a bit closer. The clincher for me would be the site work with the insulated rear wall. That would add a bit to the price and likely put me somewhere in between your number and the higher numbers posted.

From contributor F:

I notice a large range of people replying. I have been a custom cabinetmaker for over 40 years. I've been my own sales person, designer, builder, finisher and installer, not to mention book keeper and financial planner. All of this because I have always thought that there was no one who cares about my business and my customer like I do. I wonder if the people who figured on a lower price ever thought about all the steps mentioned above when they came up with their price. Even if I would get parts made by other shops, I would still have to bring the project together and end up with a finished project that, first of all, I would be proud of. Then there is customer satisfaction and all the work that went into getting the job and all the work after the completion (paper work). We have always had to compete against other shops that have no insurance (liability, health, and workman's comp), no thought for the future, and no pride in their workmanship. So you figure your price according to your workmanship, not just to the hourly rate or how fast you can get the job done, or the going rate. Remember all those other guys are just trying to be the lowest priced guy in town.