Question

We have a product line which has machining on both sides of parts. How do I set this up on a flat table machine? I have pins in one corner. I need this to be nested on a 4' x 8' sheet. Any suggestions on techniques would be much appreciated. Machine is an AXYZ 4008.

Forum Responses

(CNC Forum)

From contributor M:

My normal method is to cut the most complex sides in the nest and cut the perimeters, then turn over the parts that need machining on the back and cut them at the pins.

You need to keep track of orientation; it's easy to put a part for secondary ops on the router in the wrong orientation, and I normally label the part in such a way to make this easy. For example, adopt a convention that your label goes in the corner of a part that then goes to the pins.

Also, be sure your machine is correctly calibrated for a home position right at the pins. Some people, who always nest, gloss over the fine positioning at the corner of the machine, or offset this positioning to allow for trim. It isn't hard to calibrate most machines accurately and well worth the small effort.

Another strategy is to trim side A on the machine to a perfect perimeter slightly smaller than your nominal sheet size and do the operations required for the backs all in one step, then turn the whole sheet over and machine the fronts and cut the perimeters.

I don't prefer this myself for cabinet parts. Secondary operations are usually not done on a whole lot of parts and I find it too difficult and labor intensive to program this way. You mentioned a product line though, and if you have a lot of repeats of sheets that you run over and over again, doing the secondary ops on a full sheet, then flipping the sheet to do primary ops and cut perimeters will work well and reduce load/unload time.

A fairly simple jig can be made to latch to the side of the table to properly orient the part. Use the machine to mill the locating faces relative to the proper home (once the jig is in place) and it will be dead accurate.

I like the idea regarding the squaring of the perimeter, which will give me a square and accurate edge for secondary operations and alignment.

I do my design in AutoCAD, then set up the machining parameters in Toolpath software, which came with the AXYZ machine.

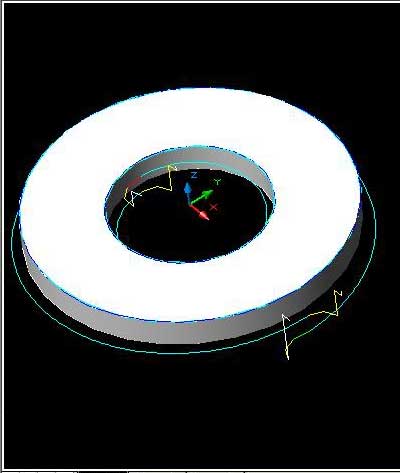

The software cuts the back side of the sheet first, then does a trim cut along the edge and side of the sheet so that there is a machined edge to flip the sheet over and position very accurately against the pins. The front of the sheet is then cut. Another option is to cut half way through on the back, flip the sheet and cut the other half way through on the front.

You can get bull nose parts without elevating the sheet. You also don't need to resurface the spoil board using this method, saving time and money.

The primary factors are:

1. Cleaning and maintaining the filters in the pump.

2. Cleaning and maintaining the vacuum seal under the spoilboard.

3. The right size and type of pump.

4. Surfacing both sides of the spoilboard. A spoilboard with through cuts will leak through the cuts, under the parts.

5. Size of the parts - some small parts require onion skinning and/or tabbing.

6. The right type of spoilboard. The vast majority of operators use regular MDF. A few report better performance with lightweight MDF. In my opinion, lightweight MDF is too porous, pulling too much air through the edges and through any uncovered portions of the face.

7. Condition of the spoilboard: damage to the edge of the spoilboard can cause excess airflow through the edge.

8. Open area on the spoilboard. Match the size of your spoilboard to the material you're cutting and gasket under the spoilboard. If the part to be cut is smaller than the spoilboard, cover the open areas of the spoilboard with 1/4" melamine or other non-porous material.

To the original questioner: This idea may well work for your application. It should be fairly easy in CAD to lay out the flip operations on the back of the full sheet. Give it some thought.

I ran an AXYZ machine for 6 years at a sign shop and a few times I had to do two sided work, since I only had clamps and no vacuum. I secured a piece of 1" MDF to the bed, then ran my file for one side and also routed four to six 1/2" holes through the material and halfway into the 1" MDF. I then flipped the sheet and inserted 1/2" steel dowels to locate the sheet after flipping to run the next file.