Question

WOODWEB Member:

I recently had to mitre a straight crown to radius crown of the same profile. After a lot of grief, we finally recognized that it is not a true miter but a miter similar to a rake. Anyone have suggestions as to a quicker way to figure out the matching angles for this type of joint?

Forum Responses

(Cabinet and Millwork Installation Forum)

From contributor P:

I have found it needs to be a curved cut. This discussion may help.

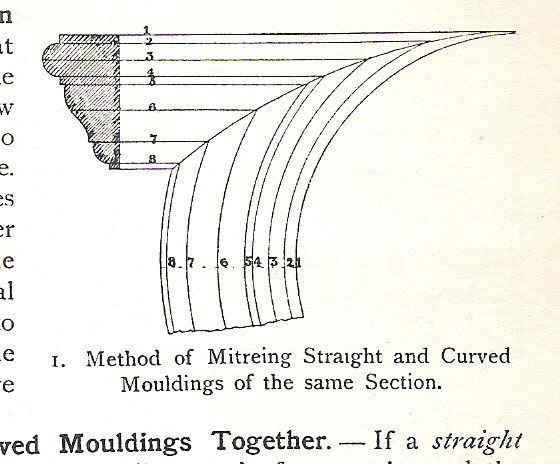

Mitering Curved to Straight Mouldings

From contributor J:

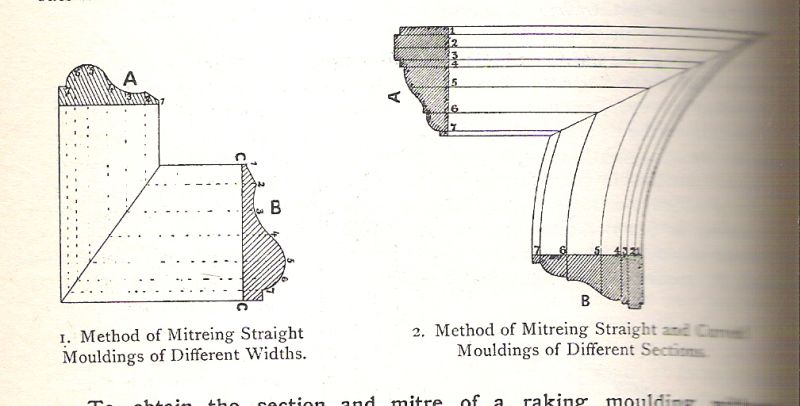

Here is one curved solution (straight out of a 100 year old book). The only difference is the projection lines of your crown molding will need to be drawn from a vertical perspective.

A bisected, straight/angle miter is only possible if you change the size and profile of the curved crown to match the straight cut.

I once worked an order for 1200 scalloped plant-on panel molding corner pieces. They were made to match the straight moldings which were all cut on 45 degree angles. The actual profile and width of the curved pieces had to be slightly different than the straight.

By doing it this way, the miter cuts on the curved pieces were also straight and parallel. A simple jig on the table saw was then used to pre-cut all the miters to perfection.

All of this falls under the heading of "enlarged or diminished moldings" to match straight or curved sections. This is a topic of various configurations and possibilities, including intersecting radii. Old Gothic-ecclesiastical architecture is often full of these mind-blowing, perfectly matched and intersected moldings.

When a customer requests it I will draw the joint for them in AutoCAD and send them a printout along with their radius mouldings (this usually easily fits on an 8 1/2 x 11 sheet). They can then lay the print out on the backs of the mouldings and trace the cut. This still requires a higher than average skill level since you are cutting from the back but will give the correct cutting of the joint.