Laminating MDF

How to glue up multiple sheets of MDF into a single thick sheet for complex CNC profiling. February 10, 2009

Question

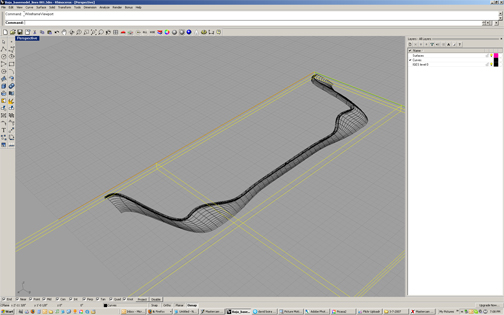

This may seem like a ridiculous question. We are product designers who produce very complex computer models in wood and solid surfaces, but sometimes we don't understand some more basic woodworking techniques. We are attempting to CNC mill the form below (an insert for a table) in laminated MDF. The piece will be 1.5 inches thick and each sheet of MDF is .75 inches thick.

In order to laminate it we have just spread lots of wood glue on one sheet, placed the other on top and have set four more sheets on top for pressure. This technique is still not bonding the pieces properly together. Sometimes, when the mill is working on a piece the sheets delaminate. Does anyone have any tips on how to laminate two sheets of MDF? It seems simple, but its not working for us.

Click here for full size image

Forum Responses

(Adhesive Forum)

From contributor E:

When you say "spread on lots of glue" you can put on too much. For spreading glue for things like yours I keep a fine grooved glue trowel and spread glue with that. It makes for nice even coverage. Also, let the glue dry at least overnight. In the center glue will take longer to dry. Check with your suppliers - someone will surely have 1.5" MDF in sheets. Scuff sand (80 grit) and blow off dust just before gluing.

From Gene Wengert, forum technical advisor:

I would emphasize the final statement made above and that is to lightly sand the MDF and veneer just before gluing to achieve fresh surfaces. Old surfaces can have a variety of contaminants, including oils or waxes from the initial production.

From the original questioner:

Thank you for your suggestions. We really appreciate you answering a question that must seem simple to most of you. Good point re: 1.5" MDF and, I hadn't thought of sanding.

From contributor R:

I too have laminated MDF but with no problems. First scuff sand both sides to be glued and apply a very thin layer of glue to both sides and press together and let it set overnight for best results.

From contributor H:

Placing four sheets on top of your lamination is doing almost nothing! To properly press this you would need a weight of 1600 lbs. per sq. foot. Why don't you buy 1 1/2" thick MDF?

From contributor M:

I sometimes need to laminate MDF together to make fixtures for one of my machines. I don't know if it will work for you but I just use contact cement, the same as you would use to laminate Formica to make a counter top. Just follow the directions on the can, pay close attention to the one that says to let both pieces become dry to the touch before putting together.

From the original questioner:

The glue seems to have held! Next time we'll implement all your commonsense and smart suggestions - the 80 grit, the 1.5 MDF, and etc.

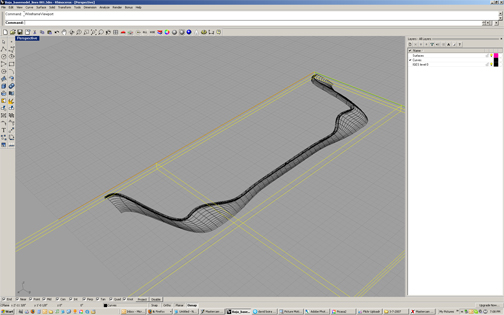

Click here for full size image

From contributor D:

For your future laminating needs, you should consider buying a vacuum bag. They don't cost much, and you will get far better results than stacking sheets.

From the original questioner:

I've had a few questions about what kind of CNC mill we use so I just thought I'd answer it here. No, this isn't 5 axis milling, just 3 axis. The bottom of this piece is flat. (No undercuts)!

I have a question about the vacuum bag: are you suggesting that we use a vacuum bag for laminating sheet into a thicker material? Or do you mean that we should make this through bent- ply method?

From contributor D:

My reference to the vacuum bag was for laminating two sheets together to get a thicker piece to work from.

From the original questioner:

You can use a vacuum bag as the clamping system essentially for laminating? Interesting - we also discovered Perfect Plank lumber, which is giving us great thickness.. Thanks for the tip!

From contributor G:

When we laminate MDF we scuff it, wet it and use

gorilla glue. Then screw the two pieces together. Let it set overnight, pull the screws out and machine. If the screws leave a hole it's ok. MDF is paint grade and you can fill with wood filler or Bondo.

From contributor T:

The last time I CNC'd

Gorilla Glue it smoked like crazy and stuck to the cutter. What a mess. Then again, maybe I didn't let it dry enough.

From contributor H:

My department and specialty is laminating panels of all types so I hope this helps. I'm assuming that the panels are 3/4" x 4' x 8' before milling. Is this an ongoing project? If so, looking into a small cold press would be worth your investment. Here is a suggestion for glue - Ultimate

Titebond III.

A 6 to 10 wet mil coverage should do the trick - you can apply with a roller and get a wet mil gage from your local finishing supplier. The glue requires +/- 125 PSI or approximately 48,000 lbs distributed equally for 30 to 60 minutes which requires a press.