Question

Has anyone out there increased the speed of their shaper to maybe 15,000 rpm or more so it would be more appropriate for small cutters? I use router bits in my 3 hp shaper every so often (especially for simple/small edge details or when duplicating a molding when it doesn't pay to grind a cutter). 10,000 rpm is not good enough. I do not want a router table bouncing around the shop - I already have three shapers. Not only that, but a router table setup can cost more than a cheap shaper. I know there is a safety issue involved, but if a guy doesn't know what rpm is appropriate for the cutter, than he shouldn't be using the shaper. And no, the side table of my tablesaw will not work - I have a support column in the way. Any input will be greatly appreciated.

Forum Responses

(Solid Wood Machining Forum)

From contributor A:

Do you know of any woodworking machine that turns at 15,000 rpm? I don't think the bearings will handle the speed and heat. You will eventually cook the bearings. Anyone who has tried to run a router bit in a shaper learns quickly that 10k is not fast enough. Grab a piece of 3/4" plywood and mount your router to it. Clamp it to a table or even your shaper if you want to use the power feed. We haven't used a real router table in 12 years.

I think this is a problem worth pursuing. Most shapers with replaceable spindles come with router collets, so someone must be using them. If a manufacturer sold a shaper with high rpm potential, I think it would be a huge success.

I have the router collet for my shaper (a Grizzly) and find when I do use it that a really slow feed rate gives me good results. Have to match the feed with the spindle speed and bit size. Yes, I do get the occasional burn, but that is the only way I can get a decent cut.

Routers and other universal motors are high speed; induction motors are rarely so. Two different beasts that operated differently. I believe when contributor A said "woodworking machine" he was referring to machines with induction motors. I would also consider anything with a universal motor a tool as opposed to a machine, but that's probably just semantics.

I've got 2 shapers and a shop built router table and use them all. My router table was built from shop scrap, as were most of the router tables I've seen in pro shops. The only guys I see spending a lot of dough on them are hobbyists who don't know any better. I do see it as an invaluable tool for my shop anyway.

Lastly, the speed a router bit needs to run at depends on the size and type of cut. I occasionally run larger router bits in my shaper at 10k rpm with no problems. Generally if they're large enough that I don't want them in the router table, they can cut well at slower speeds. Sounds like you're experienced enough to know what speed you need for your cutters though. Contributor O mentioned 12k rpm and that might be possible using larger pulley drive without pushing the limits of the bearings too much. Of course it also depends on what type of shapers you have and the quality of the bearings in them.

A router table in its most basic form is simply a router motor and base fastened underneath a piece of sheet stock with a straight piece of lumber for a fence if required. I built my own table about 25 years ago. I laminated the top both sides and edged it with hardwood. I used a large variable speed Porter Cable router (still works great... lot of hours) and built a heavy stand with 4x4 fir sized for my height. The unit is on casters and has storage in the base for all bits and everything else related.

However, I have saved the day on quite a few construction sites by making a router table with a piece of scrap plywood, two by four fence, a couple sawhorses and about 15 minutes elapsed time to make a difficult task possible.

Last summer I made a table saw from a skill saw with the same technique. If you know what you are doing, these tools are as safe as anything else. Sure, a portable table saw is a better choice, but if time is tight...

The biggest problem you will encounter is that the shaft assembly supported by the bearings is not dynamically balanced to 15K. If your machine is rated to run at 10K, the shaft was probably balanced to 12K, but you will never know.

I did modify an import to run at higher speeds many years back. I added an additional pulley to both the motor and shaft assembly. The pulley greatly affects the balancing, thus the means of mounting should be done in a machine shop. After all my fiddling around, I just bought a big router and mounted it in a router table. Much better. Sold the import shaper and bought a real machine.

Still, 99% of the time I prefer using shapers with shaper cutters.

Reminds me of a funny experience I had in a shop. I worked a few years for a man who made a catalogue full of small wooden things for preschools (Montessori). The bulk of the products he made and sold used small finger jointed boxes in one form or another. He had a part time worker that had been there for years after school, on weekends and school summer vacations, etc. The vibrator sanders in the shop were Porter Cable 505's and were all used upside down on the sanding table. The worker held the boxes or whatever object was being sanded in his hands instead of holding the sander itself. The sanders were all resting upside down on shop made holders and it was the perfect way to finish sand these small items.

Since I had cabinetmaking experience, the owner decided to have me design and build some small preschool classroom bookcases to add to his product line. I will never forget the day I came into the shop and saw the part time worker holding a 12" deep x 30" wide x 32" high Baltic birch bookcase in his hands while attempting to sand it on top of the sander sitting upside down on the bench. He simply had never seen a finish sander used while the sander was held in the hands.

I'm looking into the Felder option and the pin router. The shaper I was hoping to use is a Powermatic 27. I think it's a 2002 unit, so I'm not sure if it's Taiwanese or not. Has the Made in America sticker, which I don't think means a thing.

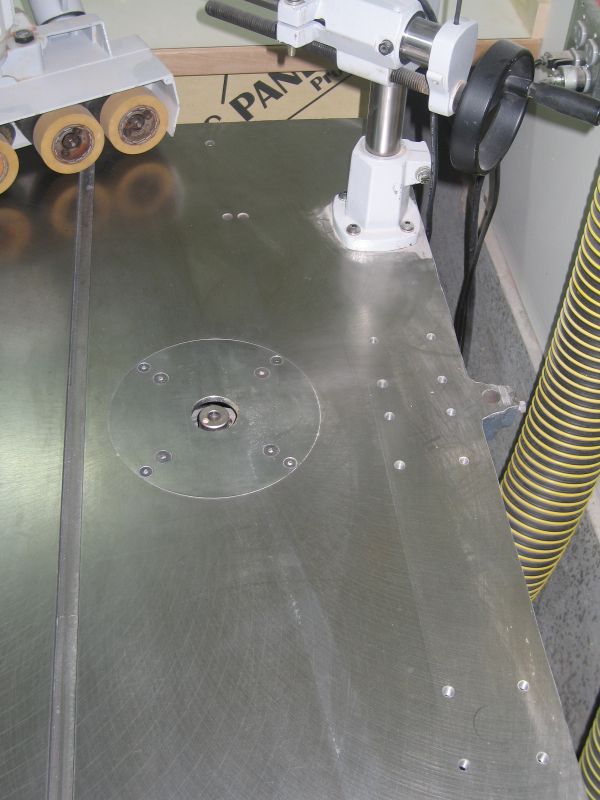

The main reason I don't want a router table is that in general they lack the beef of the shaper. With a shaper I can mount the powerfeed in several locations and I know the fence can handle the force of the powerfeed. I have considered gutting an old shaper and having the top machined (by my very generous brother) to accept a router motor insert. This is just something I've had in my head for a while and thought it might be worth putting out there.

I believe my old Onsrud machines are rated at 9hp continuous duty and the high frequency operation makes them truly unstoppable. The big cast iron table travels up and down about 15" as well as tilts. I bought one at auction (about 15 years ago) and paid less money for it than for a new 3 1/4hp Porter Cable. I had to get some new bearings for it, but that was it. These older routers are especially easy to pick up now since most are being traded off for CNC machine centers. In my opinion, a traditional pin router is still the most versatile machine in the shop and I wouldn't be without one.