Let's pretend for a moment that a woodworking company has had some success. They have good profit margins and a shop that is well organized for the volume that they produce. Let's fantasize for a moment that this fictitious company has the ability to simply double their size. Would this company be better off reproducing the exact blueprint (personel, shop space, etc) that lead to the success of the first company, or should they rethink everything?

Let me elaborate: Lets say they have a nice little balance going that consists of 1 draftsman, 1 foreman, several workers, and shop that's nicely divided into woodwork, casework, and finish departments. Do you build a second shop next door that is the mirror image of the first, in theory reproducing the success of the first, or do you uproot everything into a larger facility to make use of shared resources, etc.?

All the processes that lead to the success of the 1st company are geared towards the type of people and the type of space and the type of tools they currently have. If the 1st company made good margins, why not reproduce it? The shop size, the work cells, the placement of the tools - all refined over 20 years. Don't you want to preserve that and simply reproduce it?

From contributor Jo

Doe to Schmoe - You do not want to create a mirror copy of the shop. That won't work as easy as it sounds. You want the good culture of the existing shop to be a foundation upon which to add more shop people, equipment and administration. New workers will fit in by copying what they see is already there.

And just coldly doubling the size and throwing everyone and everything into the pool also will not work. You may need the space earlier than later, but grow slowly. Add a person here and there, then some equipment, then a few more. Let everyone adjust to the new before you shake it up again.

Personally, I would think real hard about disturbing a good situation like you appear to have. That may be why you wish you could just do another shop just like the existing. You might be better off growing very slowly and raising prices to control volume.

Bigger is not better across the board - it takes real leadership and hard work to grow successfully. Even so, you can do your best and the economy can go into the tank and you will follow it, despite your best efforts.

From contributor Je

Here's my thought for what little it's worth. Generally it's not likely that you'll double your business overnight. So you would have to invest a LOT of capital into opening a second similarly sized and equipped shop. That will take some time to start being profitable.

Alternatively you could instead focus on growing the current shop. Say buying a CNC router for instance. Or if there's one in place already, upgrading it. Of course it doesn't have to be a CNC but any piece of equipment that will enable you to improve production. I don't believe any shop is truly in a place where it cannot be improved upon. And possibly one of the most important things is having a good crew in place to incorporate the new talent.

My previous employer had moved through a couple shops before I worked there. One of the "started out in a basement shop and made his way up" stories. The shop he had when I was there was the largest shop I had seen at that point. He was there for several years or so and expanded at least twice. Finally a couple years after I left he went out and bought a 100k+ sq. ft. plant and completely outfitted it with new stuff. So looking at that I'd say growing the business is the way to go vs trying to duplicate it. But again, just my perspective from the bottom of the ladder;>)

good luck,

Jeffd

From contributor du

I usually do most of my expanding each year around the holidays, the problem is the shrinking after that.

From contributor Pa

Does the operation you are starting with actually exist? If so, can you give us some numbers to work with? Gross sales, payroll, profit, anything?

On the face of it, the answer is: you don't double every aspect of the operation. It's much smarter to try to move twice as much work through the first space. Why would you buy duplicates of the heating, the A/C, the bathroom, the parking lot - I think that you can see where I am going. For your premise to make any sense, it would be necessary that EVERY resource be utilized at the same rate, and that ALL of them have reached maximum utilization at the same time. That never happens. So some resources don't need to be doubled in order to double your work flow. The trick is figuring out which resource is limiting you now, and increasing that one first.

From contributor Bo

A second shift might do nicely. Otherwise, my vote is to multiply the locations of operation. Having the ability to scale backward can be a good thing.

Also, every new capacity plateau brings a whole, new set of dynamics & learning curves... going up, or down. So, nothing is quite as easy as replicating a sweet-spot!!

The sticky wicket is the expensive equipment... possibly it could remain a shared resource- cleverness required.

From contributor pa

Where do you guys get this idea of a duplicate shop?

From contributor Bi

I think we need more information. How you cut and machine and how you finish would be a good start. I would not want to manage 2 operations. If you do not use CNC equipment in some form then that is an area to look at. It is a foundational change to how you manufacture and done correctly it will increase your throughput and quality.

Good luck

From contributor gr

How many hours (days) each week are you currently running your shop?

From contributor Ro

A business is not just a system. It's people that have learned that system. The problem with the scenario of just opening a like shop is you don't have the most important ingredent, no matter how many CNC's you buy, it's people with knowledge.

You can only find so many good finishers, even less that will follow "your" system. That drafting person who has spent years learning your system and knows all the in's and outs, will take years to get to that same level of competency. Same goes with every position, to a lesser degree with assembly guys. But you only have so many hours to manage and your sales guy only has so many hours to draw and sell.

And if you do do it, and you take the time and money and invest it and get everybody up to speed and putting out a product at the same rate, quality as the first shop...you know what happens? The next downturn.

Grow and grow slow unless you have a very deep bankroll and don't mind throwing money at a problem with a good chance of not seeing a return on it.

From contributor Jo

Thanks for the responses.

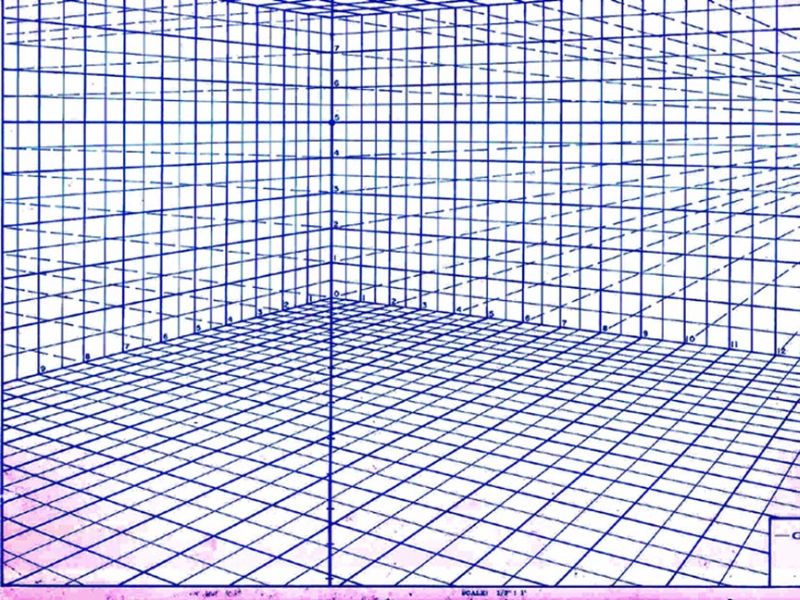

I posed this question not necessarily with the tangible idea of creating a whole other shop "next door", but more with the idea of creating a blueprint "division" within a shop. We have a condo style warehouse facility wherein casework, woodwork and finishing occupy separate, but connected spaces. We need more capacity in woodwork, but not in casework and finishing. I have an opportunity to expand into a 4th condo immediately adjacent to the 3 that I already occupy.

The woodwork shop is setup perfectly. It has all of the tools necessary, and the spacing has been perfected over many years. Between the current woodwork shop and the new woodwork shop would be the casework shop. I do not want the time and expense of uprooting the casework shop and shifting it so that the woodwork shops would be next to each other. Therefore, the decision I am faced with is this: do I recreate the current woodwork shop down to the last detail (every tool, every clamp, etc) or do I change the way we do things so that 1 shop contains the wood processing, and 1 contains the assembly? Effectively, the sawyer would cut in one shop, transport product 60ft smack through the middle of the casework shop and into the woodwork shop where the assemblers would be. Obviously, that sucks. So does purchasing two of everything. So does moving a mammoth router that would require a boom truck and thousands of dollars in infrastructure changes.

So for all intents and purposes, my original question was accurate. Recreate a duplicate shop? There is no "expand slowly" scenario. I'm doubling the capacity of our 1,500 sq. ft. woodshop, basically overnight. For many people, this in fact DOES represent a whole cabinetshop.

Does this information change anyone's thoughts?