Hidden Dowel Joinery for Closet Shelf Assembly

Advice on how to assemble a closet shelf system on site with no visible fasteners. January 20, 2010

Question

I'm just getting starting on a custom closet. This one is a little different as it will be built from veneered ply with hardwood edging and the customer doesn't want to see any fasteners. I'm planning on using dowels to joint all of the butt joints.

The problem lies with how to get the joints tight without cams or other exposed fasteners. Everything will be assembled on site (stupid elevators). I was thinking about shooting brads diagonally to hold everything semi-tight until the glue dries. Any thoughts?

Click here for full size image

Forum Responses

(Cabinetmaking Forum)

From contributor Z:

Colonial saw used to represent a gizmo that tightens totally concealed knock-down fasteners. The hardware itself is similar to cam-lock you see everywhere. The difference is how the cam-lock is actuated. Rather than an exposed screw they rely on a magnet. The drill itself is an electromagnet that causes the cam to rotate over a pin. A bit pricey per fastener but probably less expensive than your other options.

From contributor L:

The

Hafele Quick Dowel looks interesting .

From contributor W:

I would like to respond to the suggestion to use the Quick Dowel. We do have customers that currently use this as the clamping device in cabinets along with wood dowels. This connection is invisible and only requires a rubber mallet to assemble the panels. My suggestion is to not use more than two dowels per joint. Add wood dowels for additional strength. There are a few important points when using this connector that will help you.

1. Make sure the horizontal hole is deep enough for the plastic insert to be completely inserted. There is a lip on the plastic insert to make sure it does not get pushed in too far.

2. When inserting the steel bolt do not over tighten the bolt, or the bolt will not make a connection. Also, if you do not tighten the bolt to the surface of the panel the joint could have a slight gap.

3. If you are building a wall to wall closet, you may not have enough room to push on the last end panel. If you have enough room to preassemble the unit and stand it up, this may help.

Remember, this is a one-time use connector and if there are any errors in assembly, it is not easy to undo them. I hope this helps.

From contributor Y:

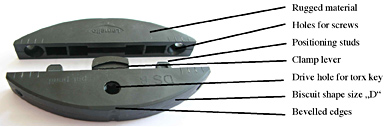

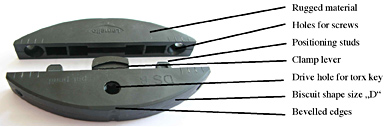

Colonial Saw no longer offers the "Invis" system which is totally invisible. Invis is still made by Lamello and is available from Invis North America. What Colonial Saw does offer, which is becoming very popular for use in Closets is Lamello's new "Clamex" biscuit shaped detachable connector. There are no visible fasteners like metal cam and dowel connectors, only a small 6 mm drill hole on the back or top or other less noticeable area. Also, plastic hole caps in various colors are also available to cover the hole to make it almost completely invisible.

They are very strong and have good clamping properties. Clamex is designed for multiple use so it is ok to assemble, detach and assemble over and over again.

From the original questioner:

Thanks for the suggestions. The quick dowel looks like a winner.

From the original questioner:

I ordered the quick dowels and will play around with them. They are inexpensive and, provided they work, they seem like a perfect solution. Thanks for the suggestions but pocket holes won't work. Everything will be prefinished and assembled on site.

From contributor L:

I have used an applied panel on ends so the fasteners, screws, will be covered. Also, I have changed assembly at times to butting the end vertical panels to the top horizontal panels so the fasteners only show from the top.