Gluing Teak to Plywood

Other Versions

Spanish

French

Advice on surface prep and adhesive choice for glue-up of teak and plywood doors on a boat. October 13, 2010

Question

I need to edgeband some plywood core with 3/8 inch strips of solid teak lumber. I am concerned about oil in the lumber contaminating the glue. Is there a special glue I should be using to make sure the teak sticks to the core?

Forum Responses

(Cabinetmaking Forum)

From contributor C:

Urea resin works well for hot pressing and lumber lams. Titebond is okay too if you cannot use urea resin.

From contributor E:

Wipe the wood with acetone and let it dry a short bit, then use epoxy. We used an epoxy (West Systems maybe?) that was pretty good. Conduct some tests so you know what you're doing.

From the original questioner:

I have never epoxied anything. Do you have to clamp it under pressure? How long would it have to be clamped? Does the epoxy make the teak slippery when clamping? Will it slide around a lot on the edge of the plywood while trying to align it to plywood? Does using epoxy require a lot of cross ventilation for fumes?

From contributor E:

Has to be clamped, nailed, screwed or such. Clamping time depends on what epoxy type/mix is used. It is somewhat slippery and will slide around. It's also messy. There are some fumes - I'd suggest a bit of ventilation.

From contributor O:

I was told yesterday that

Gorilla Glue works well.

From contributor R:

I have used

Gorilla Glue with good results on teak.

From contributor W:

I recently replaced the floor of a 46' sailboat with 1/2" teak lumber (1200 l/f 1/2" x 2"). The substrate was 3/4" marine ply. I used

Titebond 3. Everything's looking good so far - the glue bonded very well.

From contributor P:

I use acetone on the joints (before glue up) to drive the resin out of the wood cells and allow the glue to enter.

From the original questioner:

Contributor W, the operative words in your response would be "recently" and "so far." My project is for Formica doors in fishing boats, so also need to hold up in marine environment.

Contributor P, how much time does it take for the acetone to work? What kind of glue do you use?

From contributor N:

The best is

Gorilla Glue- any hardware store will have it.

From contributor P:

I just use acetone for a few minutes before the acetone evaporates quickly, so there is no point to leaving it there for very long. Resorcinol or plastic resin glue. I'm sure resin would work fine too. I like the viscosity of the others as it fills better. Resin turns thin just before it kicks. However, you can use the micro spheres to give it more viscosity.

From Professor Gene Wengert, Sawing and Drying Forum technical advisor:

As stated, it is critical to remove the oil first. Acetone works well, but use lots of ventilation and then glue ASAP - within minutes. Many adhesives work well with a clean surface and not just the one or two mentioned so far. Do you need a waterproof joint?

Epoxy works well, but it requires a thicker joint than most other adhesives, so over-clamping (too much pressure) will give you a poor joint. There are many formulations of epoxy. Some will survive exposure to UV light, but others will not. With Gorilla Glue or other PUR adhesive and epoxy, venting is critical. Depending on the service you need, there might be better adhesives than some of those mentioned. However, with interior use, all common woodworking adhesives provide a joint stronger than the wood if properly applied

From the original questioner:

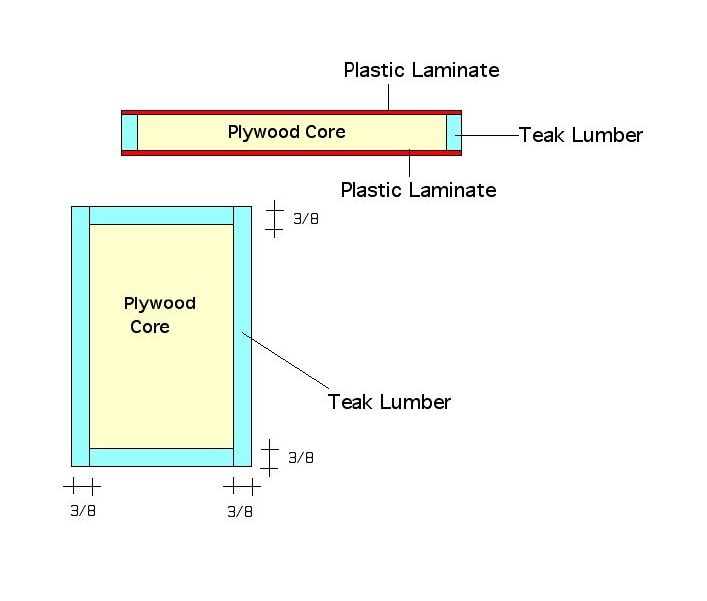

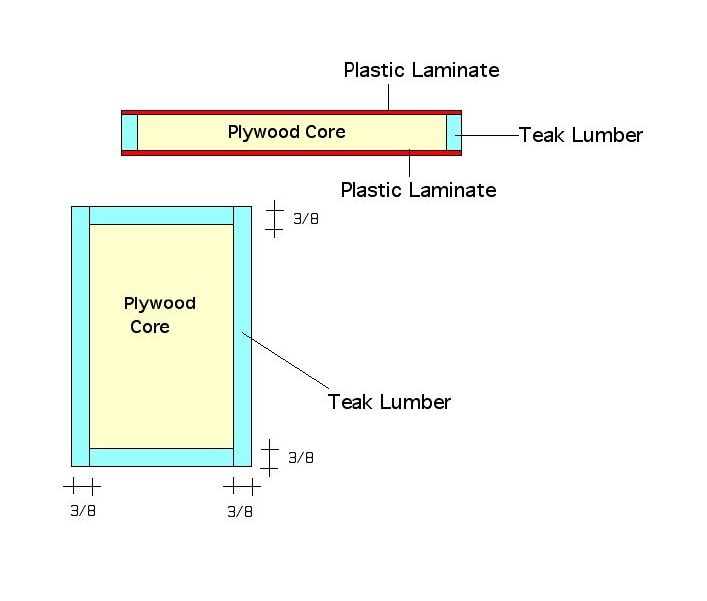

These are

cabinet doors that are intended to go into fishing boats. They will have plywood core. The edges will be banded with 3/8 teak. The faces will be plastic laminate. What kind of glue would you recommend for this project?

Click here for higher quality, full size image

From Professor Gene Wengert, Sawing and Drying Forum technical advisor:

Do you want to glue the teak to the plywood edge? If so, edge gluing is really tough for any wood species. Could you put a groove in the teak?

From contributor P:

I would put a groove in it because it will make assembly easier and faster as well.

Plastic resin glue would also work well with the Formica, except if you use a vacuum bag on plam, it will draw the glue onto the plam. I would see if you can get the lam with a peel coat. If not, I would just use contact cement.

From the original questioner:

These doors are going to be banded on four sides with butt joints at each end. There is no budget to miter the corners, so I can't see how to introduce a kerf or spline into this construction.

I don't understand how edge gluing solid lumber onto plywood itself is terribly complicated. My question is only about what kind of adhesive would be appropriate to make this happen with teak. Could it be that the glues that work with teak don't lend themselves to clamping with pressure? We've been doing this for 30 years.

From contributor P:

The way I look at it is that milling is a small but important part of the job. You will make the money back from extra time on milling by saving time on glue up.

Regarding the glue theory, no, that is not the case. And your question regarding what glue has been answered many times. I think you need to do some samples to get some certainty in this process.

From Professor Gene Wengert, Sawing and Drying Forum technical advisor:

The groove is for the plywood and not the butt joints.

From the original questioner:

Gene, are you saying we groove the perimeter of the plywood and simply butt the lumber to the plywood edges? Does this provide some kind of place for glue to get purchase so that it is not all squeezed out during clamping? In a way that seems like it would produce a viable membrane between lumber and plywood. Is this the correct thinking?

From Professor Gene Wengert, Sawing and Drying Forum technical advisor:

Not exactly... I would groove the rails and stiles. The groove in the stiles would not go to the end, of course.

From contributor P:

Why not just cope the rails?

From contributor C:

In my first reply I did not know this was a boat. The helpful responders are making this very complicated. Butt glue the teak to the plywood with epoxy. You are putting PL over the banded panels and that will reinforce the edge gluing. That will work and it's easy. There is nothing to be gained by gluing using tongue and groove, miters, splines, dowels, etc.

Acetone is a good idea, but I never had issues doing bent lamination with teak veneer for exterior boat stuff.

What glue to use for the PL is another matter, but you did not ask that. A good source for epoxy is U.S. Composites, in West Palm Beach.

From contributor P:

There is something to be gained by the tongue and groove thing.

From Professor Gene Wengert, Sawing and Drying Forum technical advisor:

The strength is based on the contact area, so a small groove actually gives quite a bit of area.

From Professor Gene Wengert, Sawing and Drying Forum technical advisor:

The gluing of end grain is difficult and about one half of the edge of plywood is end grain. Butt gluing is an option, but the strength would be low unless you used a fillett, which would not look nice on a cabinet door. This is the same reason that a miter joint has some appeal to many, or using t&g or mortise and tenon when joining two pieces at right angles. Correct MC is important because if the MC changes, the stile will move but the rail will not, so the joint may open a bit. For boats, you need a higher MC than for a home. I used West System epoxy for my boat.

From contributor J:

This seems to be a pretty simple project that many are making too complicated.

My process would be:

- cut plywood

- edgeband with teak using automatic edgebander with high-grade rubberized hot melt

- calibrate door on widebelt so it's flat and edgeband is dead even with face

- press laminate on door with cold press using urea formaldehyde

I wouldn't use epoxy because the glue joint is sensitive to thickness, as Gene mentioned. Also U-F will sand off easier than epoxy when it drips on the finished edges. Also, I think U-F is cheaper.

I haven't seen any real science showing the benefit of an acetone wipe down on teak improving glue joint performance over just a freshly milled joint. If it's out there, I'd love to see it. I understand the theory behind it, but I wonder if it confers a significant and measurable advantage. My experience with gluing teak is that freshly milled and well-mating surfaces make excellent glue joints, just using Titebond.

From contributor J:

Actually, cruising around the web, it looks like FWW tested the acetone wipe down process and found no appreciable difference in glue joint strength, whether it was wiped down with solvent or not. Haven't read the article; looks like you need to buy a membership to view it.

Purportedly, lightly sanding the joint did increase joint strength. This is all secondhand information, so take this with a grain of salt and look up the study on FWW if y'all are interested.

From contributor P:

Contributor J, I like your ideas on how to do this much better. Teak is some damn oily wood with grit in it as well. My empirical knowledge on this is yes, it does make a difference when you use acetone.

From Professor Gene Wengert, Sawing and Drying Forum technical advisor:

I can recall tests that were done at the US Forest Products Lab that showed the benefit of wiping teak before gluing. However, it is possible that today's teak from plantations is not as oily. Of course, if there is a fifty percent strength loss, but you only need forty percent of the maximum joint strength, then there isn't a problem.

The real question is how strong and durable a door is needed. The better door will cost more, but maybe it is better than needed or than a competitor will be making. It seems that Chinese furniture and cabinets and even plywood have taken the approach of lower quality, which is not a loss to the majority of the people buying furniture, cabinets or plywood.