Question

It's happened again: I've had a cabinet shop for 35 years and have always hated to do my own finishing. Despite that fact, I've managed over the years to become halfway competent in finishing, but have tried from time to time to subcontract out the process.

I just tried it again and came up with the same result, despite the recession we're in: I got prices from two finishing guys for approximately $1700.00 and $2300.00 for a kitchen consisting of 42 doors and drawer fronts and 30 lineal foot of crown moulding. That's it -there were no boxes to finish since I use melamine frameless construction. It was a simple stain, tone and topcoat job in alder.

As usual, I reluctantly did the job myself (without a helper) and, as usual, it took two days of hard work and about $120 worth of materials. I bid my work typically at $50/hour, so this finishing operation would have cost me $1120.00 if I were my own subcontractor.

So my question is this: If a finishing contractor did this job, he would probably have a lesser-paid helper to assist with the muscle work. He may or may not have had a shop, but finishing equipment doesn't typically involve a large investment, so that couldn't add much to the cost. So why can I do a competent job myself and come in so much cheaper even at my regular (skilled) rate of pay?

Forum Responses

(Finishing Forum)

From contributor B:

If you give me the square footage of this job, I can tell you if the price that was given is too high. It sounds like a pretty fair price! Did you finish the backs of the doors? What state are you in? Are these finishers that you're trying to contract with working out of a garage or do they actually have a shop?

As a finish shop only, my shop rate is a lot higher than $50.00 an hour. My cost on a monthly basis for my finishing facility is around $5800.00 and yes, I do have a mortgage. You may have to look at it this way. Can I make more money finishing or cabinetmaking? It could be the best built cabinet in the world, but if the finish is crap, the whole job is crap. On the other hand, same cabinet with a quality finish and the results are much different.

You mentioned the recession, indicating that the finisher should do the job for less money. Did you ask the finisher to bid the job with you? Or did you contract the job and then look for a finisher? You need to form a business relationship with a finisher who is going to work with you to get the contracts. Then simply add their price to your price in the bid. You stated that you got two bids on this job, which leads me to believe that you did not ask for a bid from a finisher ahead of time. With my customers, the more finish work they give me on a consistent basis, the better the price. Melamine construction just screams to me that everything about this job is the price.

And no, the job was not crap because it was melamine. Lots of folks like the durability of melamine over plywood, even the factory-finished plywood. I even gave the customer a price of $400 more to use pre-finished maple plywood instead of melamine, and they declined. Believe it or not, it wouldn't have cost me even $400 more to use plywood ($57/sheet versus $26/sheet for melamine times 10 sheets, but I rounded up). The kitchen total was $6900.00.

Yes, I finished the back of the doors. The house I put this kitchen into is for sale at $789,000.00. There was 120 square foot of doors and drawer fronts.

I didn't expect these guys to give me a great price because of the recession. I just put in the part about the recession to show that it is even more amazing that these guys don't bid competitively, even now. Both these guys have shops. (I didn't actually visit their facilities, but was informed of this by my door company's salesman, who gave me their contact info and mentioned that neither one was busy at present.)

And all this occurs in the LA market, where there is a huge underground economy and I could get Latino labor to fairly skillfully finish this kitchen on site for a lot less than even I cost.

I have always bid in finishing as 20% of the labor of a kitchen job and this has always been fairly accurate. If I had used the guy with the $2300 bid for finishing, that would be 33%. But as I alluded to earlier, these overpriced bids for finishing don't surprise me - they seem to be the rule rather than the exception.

Build a relationship with somebody and get consistent pricing you can use with confidence.

A $6,900 kitchen in a $789,000 house? I am East Coast and don't get LA. Most of my customers see the kitchen as the heart of the house, the cabinetry as a symbol of affluence. A kitchen priced at less than 1% the value of the house is like wearing $19 sneakers with a $2,000 suit. I think something is wrong with this picture.

"I have always bid in finishing as 20% of the labor of a kitchen job..."

Your 20% is low. One-third of the cost of the kitchen (not just the labor component) before installation is closer, which then becomes 1/4 of the total cost. Other ways of calculating include number of coats X sq ft X (base price + difficulty up-charge).

Here's an example I dug out of the KB:

Finishing Prices

You left coast guys must have a much tougher market out there. I can't even do a medium sized kitchen for $6900.

The general contractor fixed the damages and spruced up the house which was actually in very good condition overall, and hired me, saying that his former cabinet source, a Mexican shop that apparently works quite cheap, had been "very rough" on a house installing a former job. I gave him a respectable custom grade cabinet job with alder raised panel doors, all drawers on base cabinets, birch dovetailed drawers, etc. And I had to be fairly competitive with his "builder-grade" quotes. But I guess that's just the LA market, at least right now. But I did fine - it took two weeks working alone and I made my rate.

One thing I don't get, however: How is it that bigger shops can't be competitive with one-lung operations like mine? I've heard this over and over from commercial contractors I've worked for. It would seem to me that having some lesser-skilled employees to do some lesser-skilled tasks would be more efficient, not less, given that they would earn less than their high skilled boss does. I must be missing something: What's the point of having employees with all that hassle, if you lose work in the process by being too expensive? Isn't the pay for you, the owner-professional, the same?

Larger finishing shops are more tightly regulated (especially so in Southern CA, I would think).

Losing work due to inefficiencies does not necessarily mean the business owner makes less money. Sure, he probably makes less money per man-hour than he would if he did everything himself, but his day is only 24 hours long. Employees, even less-than-ideal employees, allow him to scale his operation and take on more and bigger projects. Yeah, his margins are thinner, but Wal-Mart makes oodles of money on very thin margins.

1. Do you prep the product before you give it to the finisher? I have some of my customers that don't do any filling or sanding, and I charge them more to do this. My finishers and I know what to expect from each and every customer, from 1 company to almost 25.

2. When you pick up your finished product, is the product wrapped in foam and shrink wrap? We provide this to our customers big and small; it helps prevent fingerpointing if something is scratched. It costs me about $400.00 a month to offer this.

3. Does the product go to the finisher complete with hardware? Some of my customers are delivering right to the job site when the finish is completed. We charge to remove the hardware and identify the pieces for easy installation when we are complete with the finish.

4. Do you require pick up and delivery of the product? We can not offer this service because of the customers' needs. Each one of my customers is just as important as the other and the time that needs to be spent on each project is critical to the project's success. I would like to have a dime for every one of my customers that said they would deliver a project on a Tuesday, only to get the call that the mechanic that was building the job did not show up for work on Monday because of the football game. We will be over on Wednesday and by the way can we still pick up the job on Monday? You see my point!

Note: backs of doors were not stained, but received same clear coats as above. This was to allow the backs to resemble the natural maple melamine cabinet interiors per owner's choice.

1. You don't have to use shellac. It has low moisture resistance and sands tike poo compared to vinyl sealer.

2. Valspar pre-cat failed the water damage test on every kitchen that I ever put it on. Switch to a post-cat or CV for kitchens.

Most guys here want to see you use a more elaborate stain program, but if the color looks good, the color looks good. The only thing about Minwax brand stains is they dry slow and I have heard some report of problems with the color bleeding. I think most guys are just bitter when they hear that the budget minded public doesn't really care about the difference between a simple spray and wipe stain, seal, sand, toner, topcoat to that of a wash coat, sand, spray dye, seal, tone, glaze, seal, sand, topcoat.

However, contributor R indicated that I can obviously finish my own stuff for less because of the cheap finishes I use. That doesn't make any sense to me since conversion varnish and pre-cat lacquer are essentially the same price in my area (about $40/gallon) What difference would it make if I am squirting one or the other as far as time is concerned?

Anyway, I only used the lacquer on this job because there was a time rush and I had to be able to build coats quickly. You have to wait between coats for conversion varnish to completely dry.

Thanks for your input about vinyl sealer being superior. I really only use shellac because I am too lazy to use another product I have to add catalyst to. And I always try to cover the shellac with something which is much more moisture resistant.

I can understand that very professional finishers like you don't like to take simple little jobs (under $1000) like what I typically have. I guess I'll just go on doing them myself.

God forbid someone spraying any product without a certified spray booth. Man, the Fire Department sure can be cruel. Same goes for OSHA and the Department of Health. Some shops operate as a single proprietor so they don't have to contend with workman's compensation.

Having one shop helper adds more money to a finishing quote. Same goes for all the other taxes and fees and red tape a finishing shop has to deal with. If you're happy with what you're doing and can comfortably sleep at night knowing you're following all the rules and regulations, and your contractors and customers are just as happy as you are with the final product, what more can you ask for?

Because of this depression, I will probably never shop for groceries at the same store again, re-new my insurances without getting other prices, or buy my cabinetry hardware, material and accessories from the same place again.

I have given away way too much money on these items in the past. I will never make what I think I'm worth, based on decades of skill and $150,000 in equipment. Let's just stop loving ourselves and face this brave new world.

The time that you spend finishing could probably be better used growing and acquiring. Develop a relationship with someone, try to work out a volume discount, and definitely work with your finisher on quotes so you don't end up being disappointed when the numbers come in.

Do what I did and keep your finishing in house. Try out some waterbased finishes so you don't blow yourself up or get in trouble with regulators. Buy a spray booth at auction or on Craigslist (they can often be bought for $500 or less, thanks to a constant abundance of failed cabinetmakers). You can keep the profits yourself, which is great in this economy. You also don't need to deliver and pick up all those parts to the finisher or waste time explaining details and requirements.

You should charge more for finishing, too. I get about $10/sf for clears, at least $15/sf for what you've described. Fact is, I don't have many jobs right now, but I stay busy building my own drawers and doing my own finishing. 2009 was my most profitable year to date!

There was a finishing company around here that used what they called the wheel style of shop setup. He had 3 booths that had separate spray areas for each booth, and 2 drying rooms for each booth. He was half the price of the other shops and his work outdid anyone around. He told us to only sand our job down to 100 grit and he would take it from there, as it was a lot easier for them to sand like they wanted. After 35 years in business, at 55 years old he sold the business and retired to Florida. The new guy ran it into the ground with cheap labor, high pricing and crap work in 2 years. The only way cabinetmakers and furniture makers will stay in business is to do everything in house. Hire the right people and get a system that works for your business.

Can I give a small example of the opposite effect? Within the last couple of years I started using my door company to make my drawers. This initially happened when their salesman approached me and demonstrated to me on paper that they could make them for substantially cheaper than I could at my labor rate. It was true, and their drawers are dovetailed and of very high quality. By their pricing, they are obviously making up in volume the profit they would have lost at these lower prices if their former work level had stayed the same. They have made the market for their product bigger.

Rarely, I do the finishing. Most of the time the contractor arranges for someone to do it and I am not involved. I prefer it that way. I have heard it said many times that a complicated finish job costs as much as the cabinets.

As far as the cabinet cost issue, I don't subscribe to the theory that many here spout; that the cabinets should cost X percentage of the house, or that finish carpentry is a percentage of the total, but I have learned over the years what cost kitchen goes into what cost home, and frankly you would be hard pressed to get a $6900 kitchen from the box stores. Most kitchens run well over $15K and the larger ones are close to 25/30K. I am in Southern California.

$50 per hour I am guessing means you spent about 2 weeks on the project. That equates to 100K a year, assuming no down time between projects and 100% productivity; and we all know that doesn't happen. By the time you pay FICA and other overhead, you probably aren't making what you should as an owner versus working as an employee. In my area, you can make $20 an hour with employer paid health care and paid vacation. That's about $50K a year. If you don't at least double that, it's not worth the risk of being in business. And just because I have a lesser paid employee, that doesn't mean I don't charge the same shop rate for his labor.

I deal with a tremendous amount of old time hand glazing, which hardly anyone does anymore, and hand applied artwork. This will always run higher than the cost of cabinets unless you're using extremely exotic woods - snake/pink ivory/Brazilian R/etc.

The last large faux job I did was for a doctor in Ft. Lauderdale, FL. I worked with a box maker - 32 mm style purchased carved crown/columns/fancy R doors/etc. He priced his work at 12,000 for the 20 some foot entertainment center.

My pricing was always separate from his as an independent contractor. I deal only directly with the customer - that's where I think most finishers working for others run into problems. They have little or no control - too many box makers just slap on 20-25-30 percent without a clue how many steps are needed to create finishes. They may even do some themselves on the low end and think they can figure from that what all future work will cost.

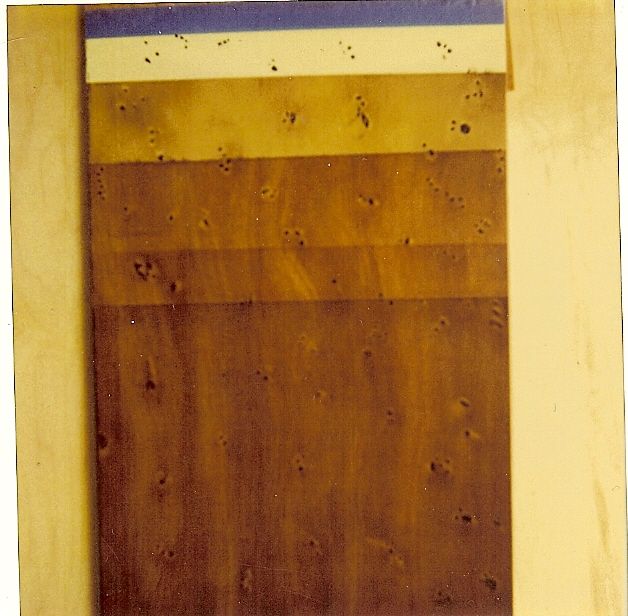

So here's my request - tell me what you would charge per square foot for this faux burl wood finish, in a $5,000,000.00 home in south Florida? Not that the home price should make any difference. It costs what it costs.

I also dye/stain to get overall background color before any pigment stain is applied. This gives me a more uniform base color to apply my glazes or pigment stains on top of. This is all stuff hardly anybody does anymore but used to be the norm. There were no amazing glazes or stains 45 years ago. And if there had been, I would have thrown them away. As finishers we made all of our own colors and stains/glazes/fillers/etc.

Those who still use these methods have to charge what I did. Those who use your methods may still have to charge more because their experience may be different - less or more than yours. When comparing end product it is just not fair to expect someone to meet your time standards. The more knowledgeable one is and the more expert at application, the more it's going to cost. You can't throw any finish my way that I can't duplicate within 95% or more, be it painted or natural/stain. Can you say the same?

My point is that some of you might be pricing yourselves out of some of the market in these trying times. Even Einstein would have gotten minimum wage if he had a job at McDonalds. So if only a hamburger job comes your way, you may need to, uh, gulp, swallow it.

I'd like to ask a technical question: When I stained this alder to a medium to dark brown, I used the Minwax stain, which is a typical oil-based dye stain, as far as I am concerned. It may have some pigment, but not much, as evidenced by the fact that even without stirring a can which has been a long time on a store shelf, you can see practically no sediment on the bottom of the can.

Alder blotches considerably, and I typically overcome this by only trying to go halfway to my final darkness with the wiping stain. The toner does the rest, but hides quite a bit of the wood grain. I have used wood conditioners, wash coats, etc. to minimize the blotches, but they also minimize the wiping stain take. Is there a simple way to go from a light unfinished wood to a medium-to-dark stain without losing too much grain characteristic but minimizing blotchiness?

I love alder and the more wild grain/knots/natural figure it has, the better. That's true of all figured woods - to me that gives character that's hard to produce. All I try to add is more pronounced highlights or character (more birdseye faux work or fiddleback where it's stronger in some areas than others to give more uniformity, etc.).

To get rid of blotching, I use a light orange dye more to the yellow side on the bare wood - no dark color at all. When I say light, I mean light! After that's applied and dried, I build two coats of 50/50 sanding sealer and sand it back to 1 coat. This smoothes out the wild grain/blotchy areas. Then use oil or japan colors mixed with MS and a little BLO to mix my glaze, which would consist of B umber/B sienna/maybe raw sienna or French yellow ochre depending.

You say a medium dark brown, so I would say B umber and maybe R umber and a touch of black. Samples need to be made of course.

The trick to giving life to the surface uniformly is with a china bristle brush, then remove any areas that get dark with a soft rag or small clean brush, then blend it back in with your dirty glaze brush to uniformity.

If you look closely at the faux wood picture, you can see where I wiped out areas to highlight them. If I wanted to make that sample uniform as possible, I would just add glaze to the light areas and blend them out with the brush - just the opposite of lightening dark spots.

You can't do that with toner or shade and do it uniformly, as you can with glaze. If glaze gets on the darker part of the sample, it's simple to just wipe it off. If it's adhered to the sample like toner/shade, then you cannot blend in the edges.

If you plan on continuing your own finishing, I would suggest you get as good as you can with glazing, and when you're real good, you will never go back to toning.