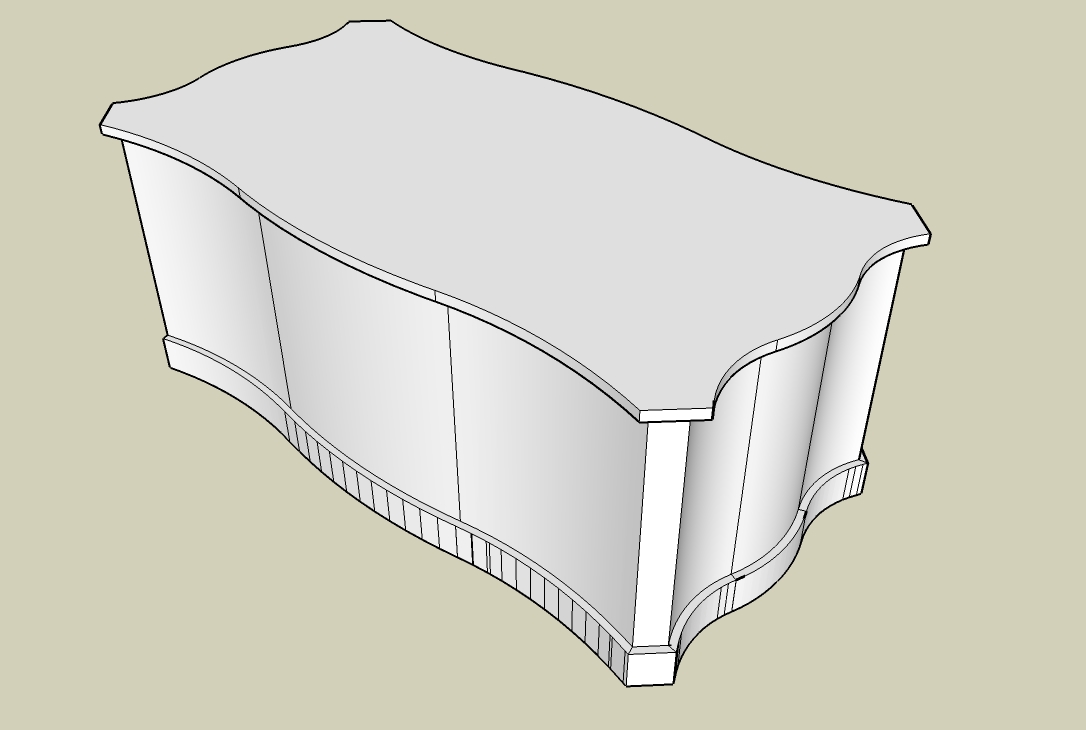

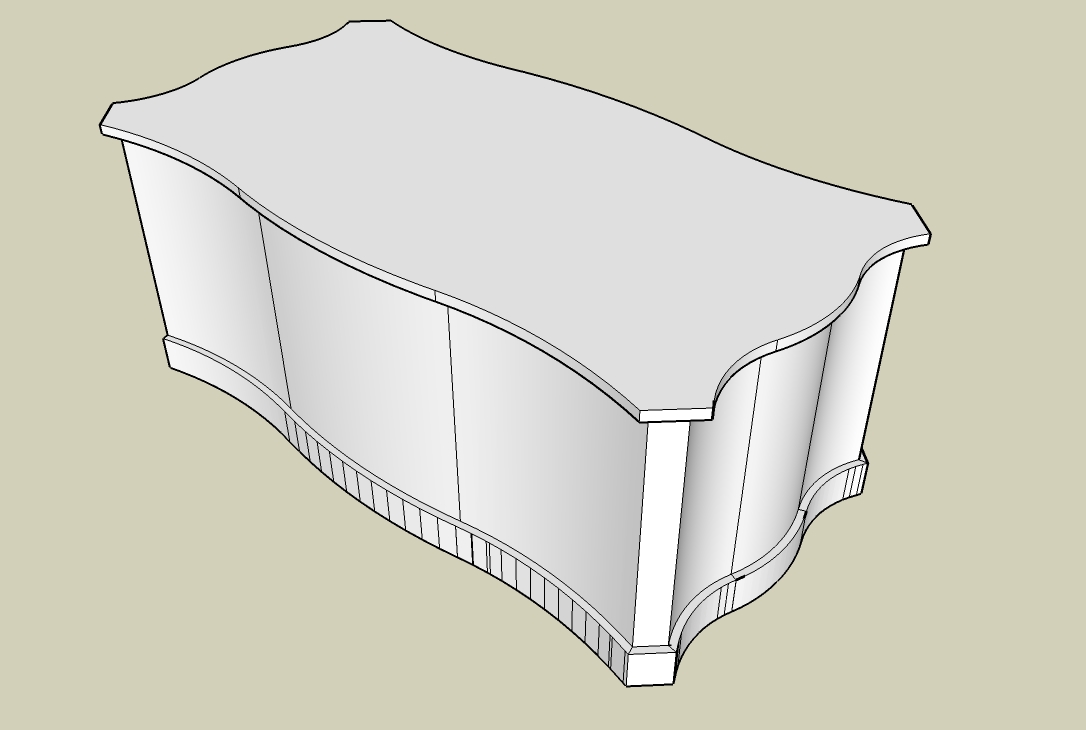

Fabricating Curved Side Panels for a Custom Desk

Furnituremakers brainstorm about how to make custom curved veneered side panels for a desk. February 15, 2009

Question

The image below is a preliminary drawing of a desk I am designing to build for a customer. The aspect of this piece that is giving me a challenge is the curved sides. My thoughts are using Timberflex or other flexible sheet stock attached to curved ribs running horizontally and mounted to a square/rectangular internal case. Then cover the flexible sheet stock with a veneer. I guess the base trim would have to be a glued-up lamination of solid wood veneers (maybe 1/8” each) shaped to fit the curves and clamped until dry, then installed on the desk. I’ll probably need to run an additional piece of trim/molding around the desk about ¼ of the way down from the top, too. Has anyone ever done this or something similar? I would love to hear your comments or suggestions.

Click here for full size image

Forum Responses

(Furniture Making Forum)

From contributor J:

I haven't done exactly this sort of thing, but it sounds like you're on the right track. I think I'd make a vac form for the sides, and after the panel substrates were glued up I'd form the molding blanks right on top of the panel so they'd fit against each other nicely. How will you handle the corners where the panels join? Rather than trying to miter everything together, I might use a vertical board as a post at each corner, and butt the panels into it.

From contributor P:

I would make a form and vac bag it. I will take quite a few hours to make the forms, but done correctly, the results will be professional. Any bulges or waviness will ruin the piece.

Do not use contact cement to attach the veneer. I this case Titebond would be fine to glue up the bender board. Plastic resin is nice because of the open time and rigidity. If you do not own a vacuum bag system, now’s the time.

Do not try to build the desk from a bunch of ribs and spars (like a boat), and form the bender board over it. You'll never get it right.

You can use the same forms to glue up your laminations for the mouldings as well. I do these types of projects regularly and find that the time spend in planning and making all the required jigs and forms is well worth it. Do it right up front and you won't fight it later.

From the original questioner:

Good idea on the post, contributor J. I'll probably go with that. I was hoping this was possible without a vac bag system, but I don't think I'm that lucky. Contributor P, I guess the ribs will be okay for attaching the panels to, but not forming them.

From contributor J:

My favorite form material is pink insulation foam. I use water-based contact cement to laminate a block of foam, using the vac press to force the layers tightly together. I cut a pair of templates from 1/8" masonite and double-stick them to the sides of the foam block. The masonite serves as a guide for my homemade hot-wire cutter.

From contributor M:

That design looks like it has two radii. If you're not into bagging it, just source two sheets of curved ply (pretty on both sides). To make the serpentine shape, glue each side up with three pieces of the same radius, arranged concave - convex - concave (sides facing out).

There even seems to be justification for a beveled construction joint between the pieces; the vertical lines on each panel: biscuit or domino together. The best part is that the facade is structural, and the inside is as pretty as the outside. You could even offer to make any door or drawer faces using the same shape.

From contributor C:

When it comes to curves, I usually have an idea or two. If you don't want to laminate the moldings, you could use compressed wood. This is an engineered solid hardwood in a variety of species that will easily form to these shapes. The challenge is dealing with having to dry the planks after you bend them, but workable ideas and options are discussed at that link.

I often build my molds from the compressed wood too, which is really convenient when you don't have a CNC router to make the flat patterns or want to bridge plywood sheets set on edge to create an undulating surface. In this way, the mold can be built up a bit like a boat hull (though more rapidly and easier with compressed wood, and with extreme curves). The finished product coming off the mold is a structural shell (vacuum bag it or other techniques mentioned in these posts).

From contributor K:

The easiest way that I can see, is to vacuum bag it. These curves are easy to achieve by using a couple of layers bending ply for the core, with whatever veneer you want to use for the face. Rather than making a time consuming crush -proof form to go into the bag, I just make them out of two or three sawn curves, with spacers.

I then glue up the whole lay-up, and slip it into the bag, and lay it on top of the form, and press it down with my hands, and start the vacuum. Once the vacuum is drawn, it would hold that shape without even being on the form. I think it may be easier to just bandsaw the trim out of thicker stock, but you could surely v-bag it to the outside of the panels . It is time to get the vacuum system.

From the original questioner:

I did a little more reading on the Kerfkore website. It seems that the Kerfkore product is to be veneered flat with a phenolic backed or two-ply veneer and contact cement and rolled with moderate pressure, then formed into radii. The instructions show the Kerfkore rabbitted and dadoed to fit over horizontal ribs. If that's the case, then I don't need a vacuum. Anybody ever used Kerfkore for an application like this?

From contributor J:

I haven't used the stuff, but the contact cement would make me more than a little nervous. My guess is that the contact cement is necessary because it remains flexible, unlike glues that are actually intended for veneer. I'm sure it would work, for a while, but I think you'd be crossing into the land of quick 'n' dirty rather than built-for-the-ages.

From contributor P:

I would build a form and vac bag it. For a core I would get 3/8 wacky wood with a 1/16 cross band sandwiched b/w to make it 3/4 plus. Unibond 800. I would cross it on both faces then final veneer. For the base, I would make a pattern of the sides after it is layed up, and then just flush cut it on the shaper. I’m not sure how I would handle the corners yet - probably solid of some sort.

From contributor A:

I think with those slight radii, you could veneer kerfkore with real glue and still bend it to your ribs. You'd have to build a press with curved cauls to do it if you're not able to buy a bag. Don't use the contact, you will regret it. It is never a good adhesive for veneer.

From contributor M:

I've used Kerfkore for a built in place curved desk. The benefit is, as you've suggested, it can be veneered flat. Then the issue is devising a hidden method of attachment. You have some trim that could conceal fasteners on the top and bottom; however, you'd need fasteners every 10"-12" vertically to minimize the flex. Kerfkore is not durable, not even a little bit, and at these slight radii, it would remain very flexible even along a horizontal axis. Of course, you could vacuum bag two pieces together, but this is tricky, as the kerfs soak up adhesive, and tend to starve the joint. For you, this defeats the purpose anyway.

I know how it is when you've found a new great product that promises to make life a lot easier. And if you were building a flashy trade show booth that needs to be built in a few hours, and last no more than a week, then I'd agree that Kerfkore's your man. If you need to use this anyway: fully encase all edges with solid wood. That should get you past a one year warranty.

From contributor R:

Contact can work just fine with veneer - the right kind of veneer that is designed for contact. I did a big (11' long) compound curve reception desk that had to be built using ribs because of the size. I used contact cement for the veneer, but the paper backed veneer with resin between the layers - worked like a charm. This piece is small enough that I agree the vac bag is the way to go.