I have been building cabinets for 34 years and now find myself at a crossroads. I am moving out of residential cabinets and more toward commercial millwork and retail store fixtures. FYI we are a 12 man shop with 10k SF. I have used CNC technology for over 7 years now and believe its the best way to go. I currently use Cabinet Vision solid w/ screen to machine. We started with KCD about 10 years ago. Both are great programs.. I also use Enroute to import DXF and DWG files for tool pathing items created by some sort of cad program.

I now need to buy a cad program to create drawings and parts for the store fixtures. I am at a loss to determine the best product for my needs. Thanks in advance for your help.

From contributor ja

Take another look at your CV,, I am sure you could do it with it..

From contributor Pa

Take a look at the thread below titled "the perfect cabinetmaking software

From contributor Sc

"I am moving out of residential cabinets and more toward commercial millwork and retail store fixtures".

That being said CV has nothing to offer compared to www.micovellum.com . However there is the price of omission to contend with

From contributor ja

And New learning Curve !!

From contributor ja

Honestly I out source most larger work to a fellow who uses microvelum, I need to qualify it as I just have no desire to learn it,, with a 12 man shop it may work better for you..

From contributor ca

You have a system in place. Send an employee to comm college and get training on autocad. Then send another.

We are a small commercial casework shop 6 people in 10k sq ft, also. Architects have not rejected our drawings and the s2m on cv has been a good transition.

We make a lot of retail fixtures, retail casework and cv has worked for us.

cm

From contributor Ad

I would agree that more training is always a good thing.

Don't let them tell you CV can't do commercial work.

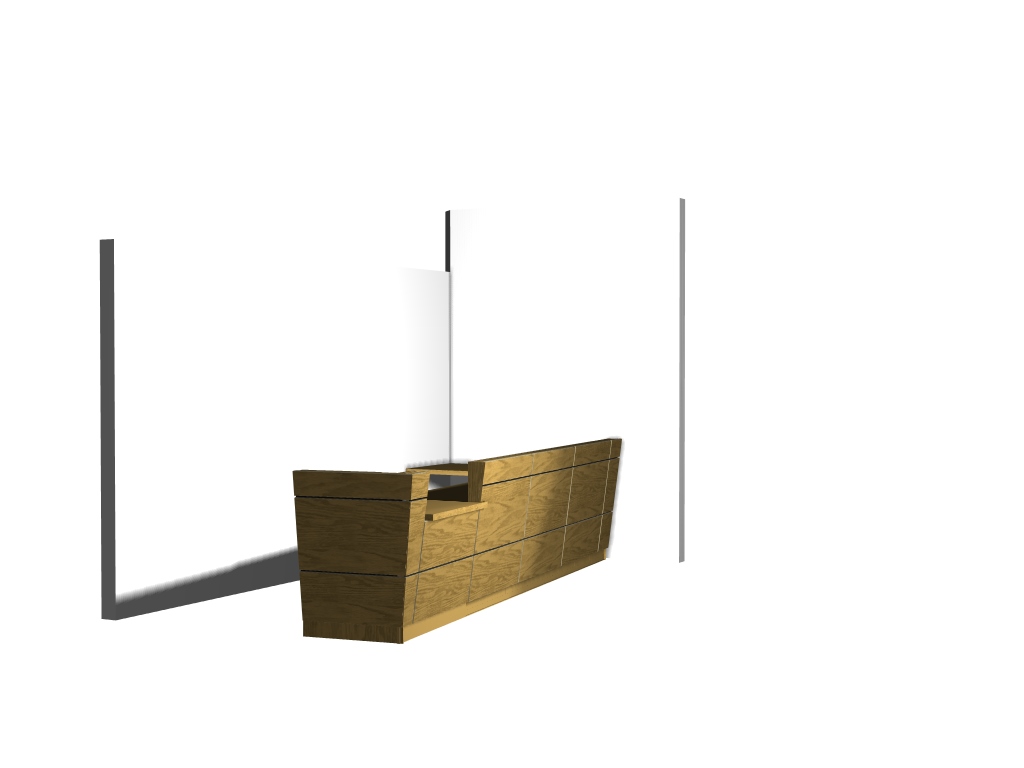

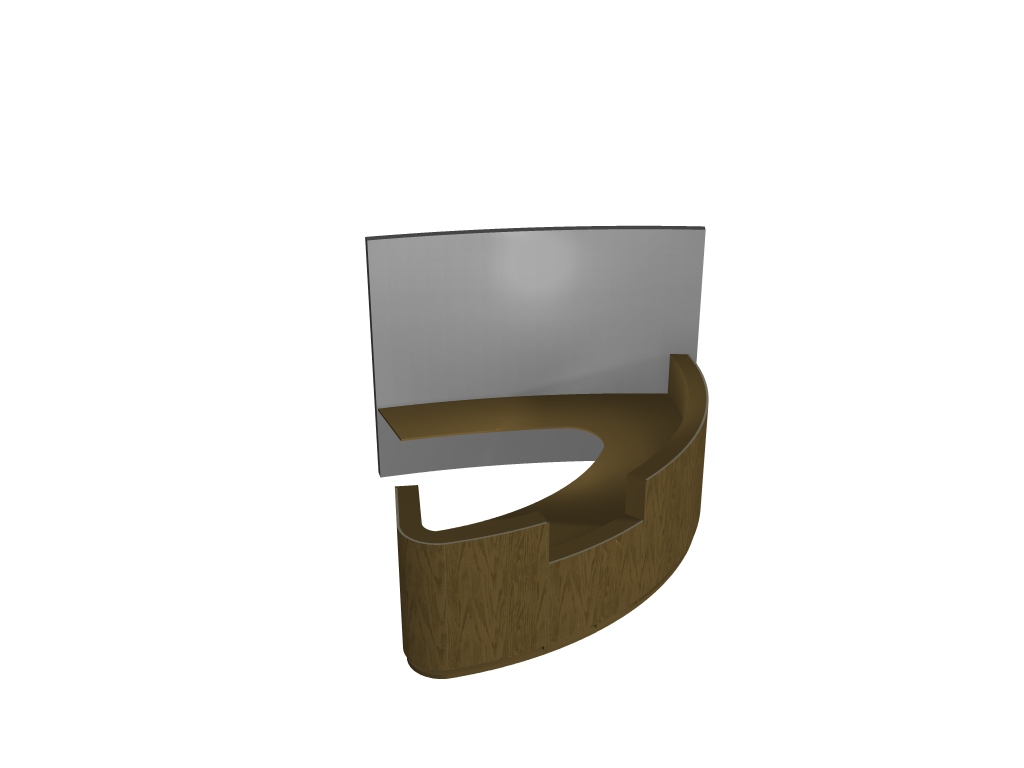

Here are a couple of reception counters that I just did.

I do not have in a transaction top since they were granite, but it would not take but a few minutes to add them.

From contributor Pa

A question for the MV guys, I watched the video at the link which was boxes.

For retail you have to do more than boxes. You have do things that are not going to benefit from a parametric setup in fact parametrics often get in the way of one off custom. Which is not a problem with Smartlister because it extracts the parts after they are drawn, for CNC and squares them up.

If you draw in 3d the sections are a snap with Auto Cad or any modeler. You can stretch or shrink easily with Smart Lister. And you can export parts to CNC with Smartlister. You can hide elements to visualize better with Smartlister. And 3d cuts down on errors due to oversight.

Last week I drew one cabinet that used 9 leather hides, architecturally etched brass, glass, and wood. This cabinet required 10 D sized pages. Smartlister works fine. The only people I hear say they don't need 3d have never used 3d.

Oh and the price is considerably better than MV's (;^)

From contributor ca

I hate to say it, but we get along just great with CV and would have bought Microvellum, but I just didn't like er, uh, a personality. I am sure it is more than capable. But, if you already own CV, I would get more training and use it. We do a lot with the program and back when I just owned "Kitchen Builder," I designed a bar with soffits and all, pretty much the entire build and it was impressive.

cm

From contributor Ke

Adam B

Could you explode the view of your cabinet to show how CV would convey the construction details to the shop floor?

Is all of the joinery accurately displayed?

From contributor Ad

I sent out a couple of drawings that have all the stud locations dimensioned out and we just glue and nail everything together.

Unfortunately we got hit with a big snow storm and I can't make it into work today.

We shipped the L-shaped one as one piece (14' long) and the curved one we shipped in 3 pieces since it had to go on the 3rd floor and the elevator was quite small.

From contributor Jo

Kerry,

Here's one of mine. This is for our own offices, so they aren't presentation level drawings or anything.

We do dado joinery between the studs and the top/bottom plates. They go together super quickly.

http://screencast.com/t/U6I4vwKeK

From contributor Pa

Jonah how many hours in that drawing?

From contributor Jo

Pat,

I really couldn't tell you. Since this was an office remodel, I just kind of did some work now and then whenever time permits. I'd say in general I spend about 3 hours or so on any given wall of about this same scope, including submittal drawings and engineering for production.

I'm much, much faster than this than the average CV user would be, though. I don't want to give the wrong impression, doing custom casework walls is probably the hardest thing there is to do inside Solid. It is something most users don't attempt.

From contributor ja

Nice !!

From contributor Le

We provide post-processing (optimization, labeling, single-part and nested part programs, etc.) to a number of medium-to-large custom fixture and millwork manufacturers. A surprising number have moved away from programs like Cabinetvision (not flexible enough or too cumbersome to make custom work) and Microvellum (all sorts of comments, mostly frustration with the complexity and time it takes to make custom work) to AutoCAD because it's simple, straightforward, and it doesn't build in limitations on doing it "their" way rather than your way. Often these customers continue to use programs like CV, MV, KCD, etc. for what they're great at - casework and other box work, and use a generic CAD program for what it excels at.

With the right export formats, CADCode (sorry for the plug) can merge and process data from all of these programs for posting to saws, routers, point-to-points, and horizontal borer/dowel inserters. At the least, consider AutoCAD as an option.

From contributor ca

Les

What is wrong with CV, Mozaik, MV, KCDW or any other of the software ? Please explain

From contributor Pa

I think it has to do with parametrics verses no parametrics.

If you can use parametrics then it will be quicker to build the cabinets. But the parametrics are time consuming to setup and only worth the effort if you are going to do more of a very similar product. The parametrics are set in stone with KCDW or Cabnetware. They are more customizable with MV or CV.

The other concept is to do what Les is talking about which is to extract the manufacturing information after the drawing is done in whatever manner is the most efficient. I have seen this being done for some rather custom but repetitive products that you might think would benefit from parametrics and it worked very well using Cadcode and 2d Autocad albeit there were more mistakes this way than there would be with 3d but it is easier to train people to use 2d and less time consuming with 2d.

Smartlister uses the same concept through 3d and it works with the added benefit of being able to visualize what you are building and is very flexible.

From contributor Da

Hi Pat,

I do appreciate the kind words about SmartLister. Thank you.

You mentioned leather was included in something you made, but not whether or not you actually used SmartLister to process the material. SmartLister is not to be used on such materials.

I am not a supporter of needless violence to life as the license agreement states:

2. License

c. Restrictions on Use

(vi) use the Software for purposes of supporting or promoting any act of violence to animals or people

Thank you for your understanding,

Dave

From contributor Da

This statement of mine is incorrect: I am not a supporter of needless violence to life..."

it should state, "I am trying not to support needless violence to life...

We are not our actions and and labeling myself was a mistake, as I cannot be my action of choice. It implies that a person may be different, when the truth is we are equal. It's a work in progress for us all.

From contributor Ja

AutoCAD is very powerful and also quick and easy to do shop drawings in. If you just need 2-D shop drawings for submittal then it might be the best choice. Sometimes its just fast to go in AutoCAD and draw a custom item, with no rules or restrictions. I have worked for several companies who use AutoCAD for submittals and then another program for generating cutlists etc. It does give you flexibility and spread out your knowledge base. For instance you could hire a CAD person to just do submittals and then have an engineer who does cutlists (in CV or ?). It will be easier to find a CAD person than trying to find a specialist in a certain program (probably cheaper too). Obviously many opinions on software but you just have to find what works best for YOUR company. You have CV already so it wouldn't take an investment to use that, I am not super familiar with its capabilities, but do know of companies who use AutoCAD for submittals and then use CV to put it on the floor.

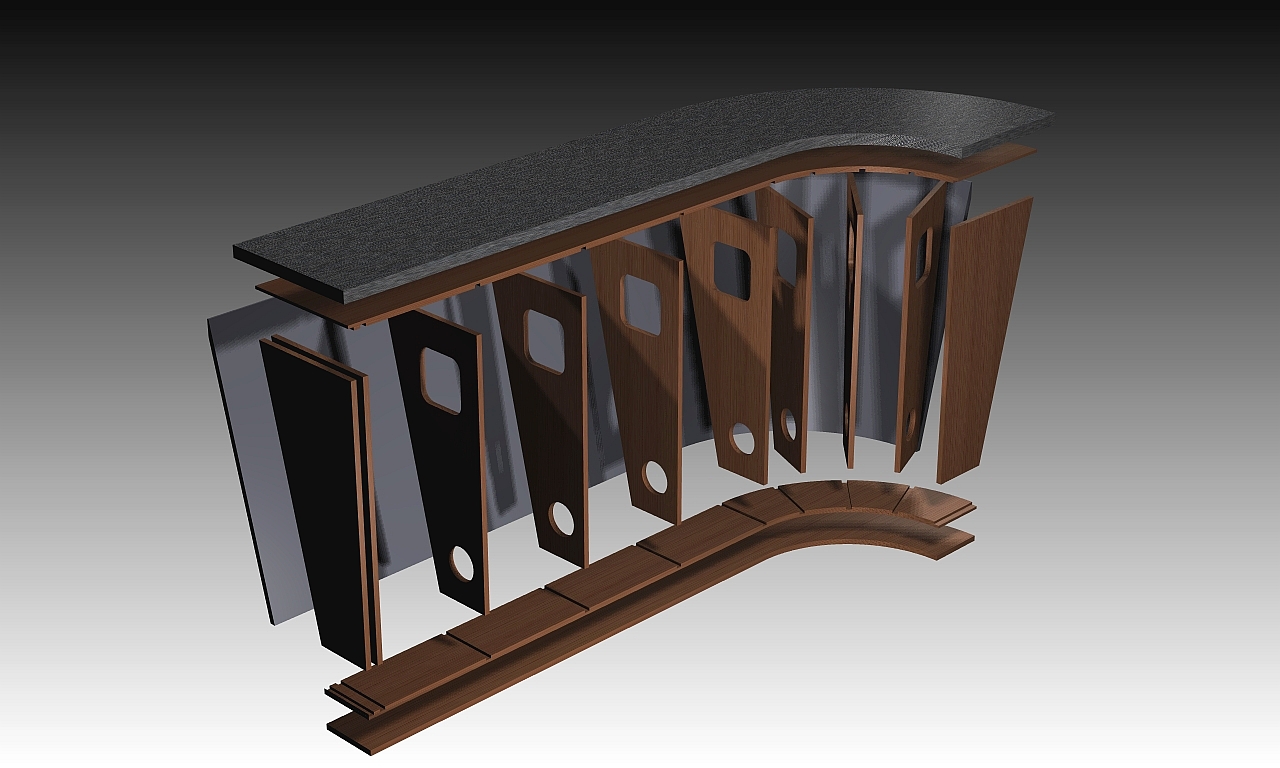

From contributor Ke

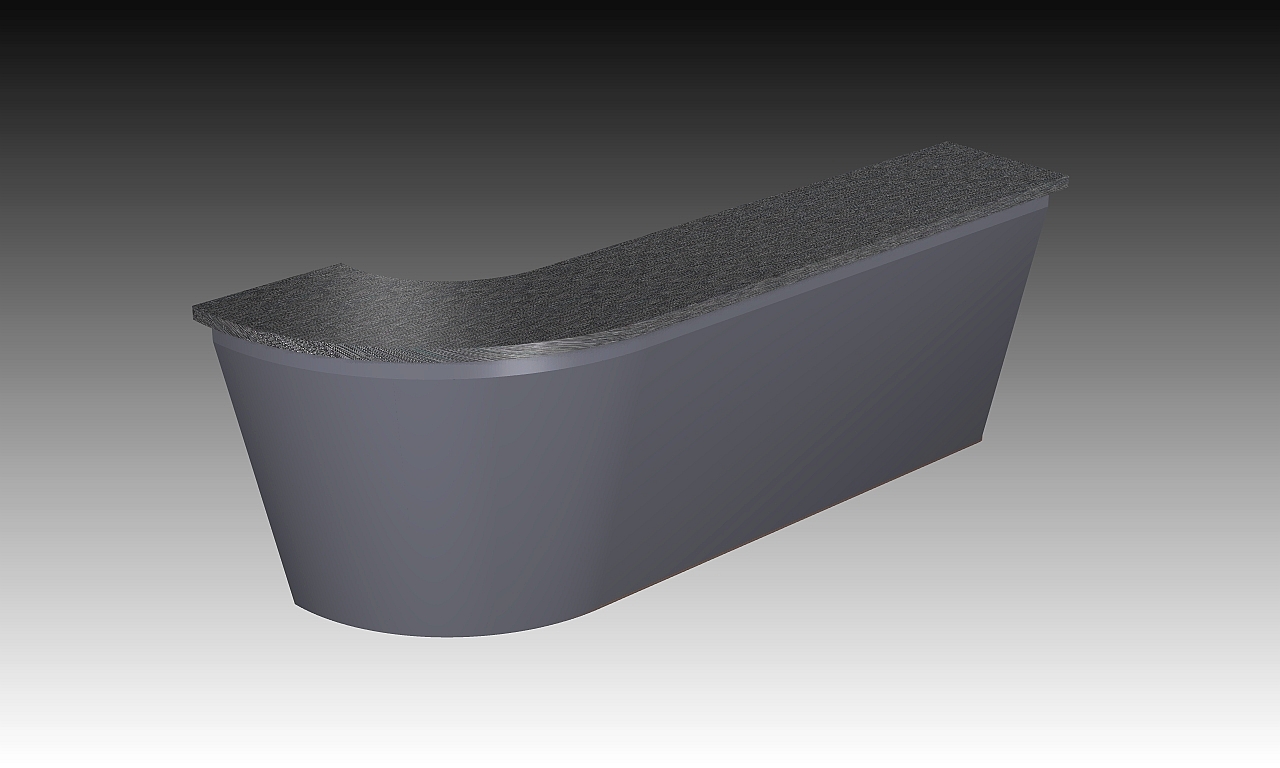

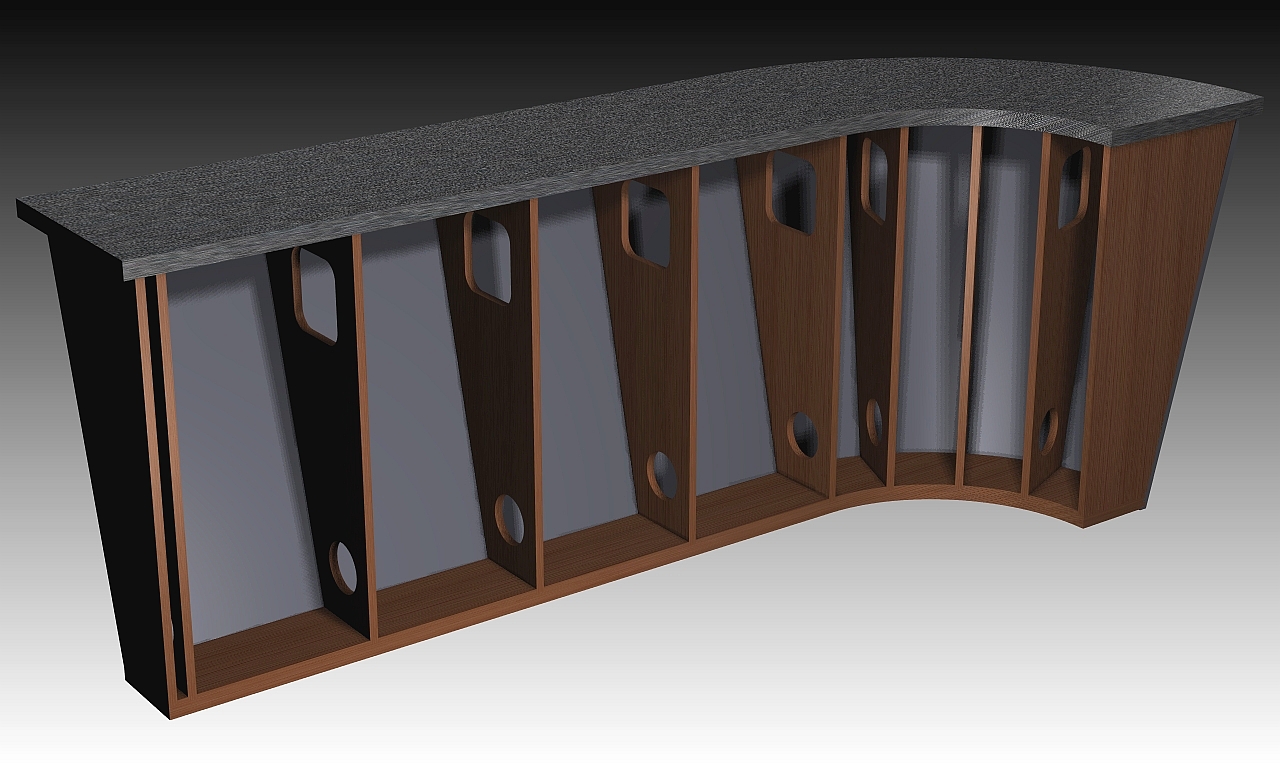

I have always liked the fact that eCabinet Systems Software allows me to create "one off" projects as parts without using parametrics or the need for a third party software.

In the example shown I simply create one part then copy and paste the rest. Each individual part can then be further edited if need be.

The only part that won't nest in this example is the curved part of the skin. eCabinets will not flatten this part for me.

From contributor Pa

I will say that the reality of one offs is they often require hundreds of parts this gets complex and the software with the most man years of development helps to organize the parts.

From contributor ca

I'm not even gonna argue any more- 48 cabinets today 2 guys. Screen to Machine with cv.

cm

From contributor Pa

You have not raised an argument?

What do cabinets have to do with the OP's question?

From contributor ca

Yep, sorry. nothing really, except that one day we cutting commercial casework with it and on the same day cutting Corian tops and Gibraltor window sills. We are mainly a commercial casework shop.

We use Delta CAD, when we have to, save as a dxf and import. Send it to the counter top area and cut it in s2m eliminating the build up. Or, draw it in the limited cad program that comes with cv and do the same.

Another example is Friday, I got a ASI with drawing from the architect on a job we are working on for hospital bed- head walls, and of course it has got to have a 14" radius @ the top blended with a 63" radius pulled from 7 feet and 9" offset to the north-dropping down the left hand side blended to a 6" radius. Long story short, called for the dxf file, imported it, snapped to the dxf , cut a sample, sent it to the job site, got approval. Gonna cut in the morning.

Cut 2 nurses stations last week, along with the corian transaction tops, and p-lam work surface for the lower. We drew those in cv and sent to the machine.

Ya, cabs, really aren't in the OP's question. But, I have altered a lot of the basic library items and sent them to the client and got them cut and shipped. From toilet partitions, reception desks, nurses stations to casework, we have found cv a good solution.

cm

From contributor Ke

Gentlemen, Thanks so much for all the informative responses.... Because I already have and know CV Solid w/ S2M, I have decided to upgrade to CV Ultimate.... I believe this program will serve me well. May God's blessing be on all of our businesses... Thanks again!!

From contributor ca

I think you will be extremely happy with Ultimate. I am sure Adam and Jonah are both operating in Ultimate and so am I.

cm

From contributor Le

@cabinetmaker - I never said there was anything wrong with CV, Mozaik, MV, KCD, etc. They all have their strengths and to the best of my knowledge, they all have users successfully making products using these software programs. I was pointing out that for the kinds of custom work about which Mr. Moore originally inquired a number of our customers doing the same kind of work have opted to use AutoCAD because of the speed and flexibility it offers. As I said in my original post, many users employ both AutoCAD and other software to cover their complete product line.

From contributor Mi

Cabinet Vision is a pretty complete solution for the modern cabinet/fixture shop. For drawing items that are not easily created in CV try looking into one of the solutions from Ashlar Vellum. Great tools for quick and accurate drawings.

Mike.

From contributor Pa

I have used Ashlar Vellum a great deal in the past. It is not good for going to CNC as it does not connect the points. It is very easy to learn but is missing many tools that are essential. It is not for 3d at all.

From contributor Mi

We are designing in 3D (cobalt) and using Aspire for CAM. It is not the best solution for everyone, but it is very flexible and fast. I usually start cutting nested shapes within 10 minutes of being given a hand sketched drawing from one of the carpenters. These can be anything from 12" circles to a life size Ronald McDonald cut out. all mixed together!

there is no issue with closed vectors during export. select the closed geometry, use the command to "join splines" or what ever.

Also you can "connect the points" (create a closed vector) in any CAM program I have ever seen. Usually just one or two clicks.

The reason I recommend the poster looking into Ashlar Vellum is that they have a great 2D drafting program that is a value for the price/features. CV will never be able to create complex 2D parts as fast as a good drafting program and Auto CAD is way overkill. The AV products are less feature heavy and focused more on getting the design into the computer.

mike

From contributor Da

Hi Michael,

I want to clarify and correct a few things with your last comments.

You mention Ronald McDonald. Do you reailize that heart disease is the #1 killer of people in the USA?

http://www.cdc.gov/nchs/fastats/deaths.htm

Did you know that science now says that animal products are not necessary for proper nutrition?

http://www.eatright.org/about/content.aspx?id=8357

Teaching children to kill needlessly and to encourage heart disease is not very helpful.

“Ashlar Vellum is that they have a great 2D drafting program that is a value for the price/features”

Ashlar does not sell Cobalt. They sell a license to use Cobalt. There is a difference and it should always be noted correctly so all understand that they are not buying the software. Some companies actually do sell software. This sort or misrepresention is not fair to them or the people shelling out the cash.

“CV will never be able to create complex 2D parts as fast as a good drafting program and Auto CAD is way overkill”

If you right-click on the Woodwizard executable, you will see that, in fact, it is an OEM version of AutoCAD.

In the Woodwizard users are restricted to working one plane, which requires rotating the part to access another side. An experienced user needing this functionality within CV can do the extra rotations very fast after a short time of experience.

From contributor Jo

CV and Wood Wizard are not at all the same thing. Wood Wizard is a discontinued product.

From contributor Mi

David,

To be frank I dont care about the health of people who make bad lifestyle choices. I swam 2 kilometers in the ocean Sunday, I ran 10 Km yesterday, and I am a amateur boxer/Muay Thai fighter. I also washed down a Bigmac with a liter of good beer last night. It means nothing. This is not the forum for sharing your personal agenda. we are professionals doing a job. I work for a marketing company and McDo is a big client. If they want 20 life size Ronalds cut from plywood it is my job to cut it. I am sure we can all live on tofu paste and carrots.... But it is an extreme minority of the worlds population that agrees with that. Try pushing your agenda on Tofu.com. They will be a more accepting audience.

I can not draw anything in AutoCAD. Not because I am incompetent, I can do amazing things with Solid Works or Cobalt and even with the assembly editor in CV. Typical 2D drafting programs are made for architects and such. When it comes to drawing a complex shape that must be dimensionally accurate I find more basic drawing programs to be a lot easier to use.

I am well aware of Wood Wop / Wood Wizard. Compaired to Aspire it is lame as a CAM. For drawing new designs it is even worse. I do not think you will find a designer who would prefer the 2D drawing functions of CV over a program dedicated to creating 2D drawings for design and product development.

The OP was asking for options to facilitate drawing odd comercial fixtures. CV does this well up to a point, but for one off items drawing in a simple drafting program then importing the vectors into CV or other CAM is the fastest I have found.

Dave, you always add a lot to the technical discussions here, mixing in political agendas distracts from your solid advice and experience.

Mike

From contributor Le

To pick up on David and Michael's exchange - it's true that this forum is about professional woodworking, but we don't check our humanity at the shop door, and it does matter for which clients you choose to work. How much control or influence a worker on the line has, or a software or hardware company selling products to a manufacturer who then produces materials for a company that in turn produces harmful products gets to be a bit dicey. I suspect all we can do is raise the collective consciousness.

From contributor ca

I think it gets out of control when it comes across as an attack.

From contributor Mi

David,

I apologize for being insensitive. I have no problems with your choices. Some of my best friends are Vegetarians... Sorry I couldn't help the bad joke.

Some of you may have noticed I spent the last few months trying to come up with a good way to take a "new idea" and take it through the design process, engineering/structural elements, presentation and approval and finally to the CNC.

I will start a new thread on what I have come up with so far.

I mention because I am in a similar (probably more extreme) situation. Despite 5 years using Cabinet Vision and Inventor I could not get my designs to the machine fast enough to meet the demands of this company. The lead time is generally 10 to 30 minutes. I have to draw it (usually just circles and simple shapes) and add the parts to a "running nest". All the while I am drawing up very complicated props like I posted in the past when asking your advise.

AV has a great 2D drawing program, and a 3D wire frame sketching program. There are none of the advanced enterprise or analysis features found in Auto Cad, but those features get in the way for a guy who just needs to draw a "cartoon looking school bus" that is 1 meter tall and 3 meters long! All the drawing tools I ever needed are there and it is fast. As for 3D solid modeling Cobalt leaves a lot to be desired.... I hope AV will catch up the product. I have not yet bought the license (they gave me an extended trial version) becuase I am waiting to hear if they will address me complaints. Or at least explain the logic behind their programs. Cobalt also crashes a lot... on MAC! It is the only Mac program I have ever seen crash. But I am still leaning towards Cobalt despite the issues... That is how much faster I am with Cobalt compared to my usual software choices.

Mike

From contributor Ch

Check out SolidWorks with the Pathfinder3D add in. It allows you to design in SolidWorks, and the automatically exports a layered DXF file for the CAM system (EnRoute, AlphaCAM, CADcode, etc), to cut.

SolidWorks is a great tool for the store fixture industry, but to be fully Automated you need to be able to export to a CAM system that is designed for the wood working industry. Pathfinder does that for you, as well as adding some other functionality specific to the out industry.

Feel free to call or email with questions.

(360) 772 3338

From contributor Pa

Cliff is Pathfinder new?

From contributor ka

there is plug in called "solid cam" that seat on solidworks

they have now post for biesse directly for 5 axiss

From contributor ud

such great insight. thanks guys!