Question

I'm doing a project that requires about 50 sheets of 3/4" oak veneer plywood, and there are a lot of dados involved. This raises the question of thickness variation in the plywood, sheet-to-sheet, and within the same sheet to get tight fitting dado joints consistently.

I'd always been told that (1) there is not much variation within a single sheet, provided you've purchased high enough quality plywood, (2) not too much sheet-to-sheet thickness variation within the same pallet of plywood, and (3) a completely unknown variation in thickness pallet-to-pallet. I'd like to know if anyone out there can tell me what to extent, or point me in the direction of the forum/knowledge base article that talks about this.

Forum Responses

(Cabinetmaking Forum)

From contributor R:

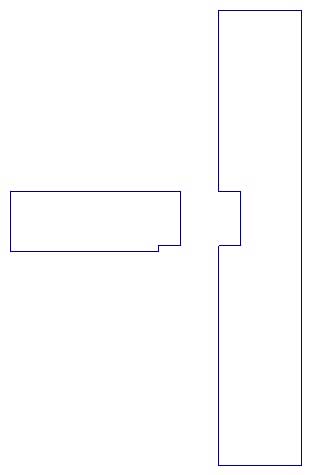

I developed my own system for joining sheatgood 18 years ago because of the thickness difference issue. I have since then used a simple butt joint incorporating a 1/4" x 1/2" continuous spline to lock the parts together. It's a joint easy to do with a tablesaw and router, or if you have it, a 1/4" groover on a shaper. You make a 1/4" x 1/4" dado in the face of your panels and a 1/4" x 1/4" groove in the edge of the partitions and fixed shelves, glue the spline in and assemble with clamps and cauls, screws or nails. This eliminates this constant fitting problem you have described and it's a very strong joint.

You will need to keep in mind that tolerances creep. An additional 16 1/64" will add up to 1/4". If you dado, and there is a variation in the thickness of your sheets, your dado depth may be correct, but your overall width will be off. 8 units with and additional 1/64 = 1/4", 16 = 1/2", and so on. When you are dealing with this may pieces, take many readings and average. The more numbers in your sample, the more accurate you will get.