Crown Moulding Corner Fastening Techniques

Other Versions

Spanish

French

Advice on using adhesive to fasten outside corner joints in large crown moulding, along with other practical tips for installing crown. October 12, 2007

Question

I have the fortune (or misfortune) to install some 8" MDF crown. I figured out a long time ago that preassembly for short runs (anything under 6' for me) is the way to go, thanks to Gary's book. On the current install I have a few 22.5 degree outside corners and one 90 degree outside corner. The 90 degree outside corner is a long run, so it cannot be preassembled.

1. Getting outside corners tight on runs that are too long for preassembly has always been hit or miss for me and caulk looks like hell. I have a clam clamp - is that worth a try on an outside 90 degree corner or are there better methods? I have always been afraid to drive a screw into the miter on MDF.

2. I hate to spring for the Ulmia clamps, as I may not have much use for them. I have the Collins and I really like them, although usually I have to guess where the best place for the points are and hit the trim with a nail set first so the spring gets a good bite on MDF. I'm thinking the Collins will work even on 8" crown if I use several and let the glue dry overnight. Is it worth a try?

Forum Responses

(Cabinet and Millwork Installation Forum)

From contributor R:

I have stopped using any nails, staples or traditional wood glue for inside, outside corners. I use hot glue sticks, or the Titebond hyper glue system (I like this the best ). You can get it in 30, 60, and 90 second set time. I did a conference facility that had about 125 inside and outside 90 degree corners and it has been installed 3 years and not one call back and not one nail. I prefer the 30 second set time, but make sure that you have a helper apply the glue and guide into place.

From contributor J:

On large MDF crown we only nail on the bottom and top edges, not on miters. For the outside corner we use glue and duct tape, pulling the miter together from each direction. If the cut is accurate, corners require only minor touchup with sandpaper before final finish.

From the original questioner:

I have used cyanoacrylate based glue for real wood and this works great, but I have found it does not work for anything on MDF. I have seen the

Titebond hyper glue system but was waiting for a non-biased opinion. I now have it (thanks) and I'll be giving it a try.

From contributor H:

The Fastcap instant glue works well on MDF, but they have 3 thicknesses. I forget which one is best for MDF, but I have used it. Check with them and they will tell you.

From contributor U:

2P10 gel works on MDF but is not strong enough to preassemble long runs of crown. I fit long runs a piece at a time. Read the corner with a Bosch angle finder and set the saw to the readings. You can also read the corner with a protractor and use a crown chart to set the saw. For crown small enough to be cut in position, I hold the pieces up and running long past the corner and mark lines on the top and bottom. Do this on both sides and then transfer the marks to the pieces themselves. Cut the crown in position, and use a laser guide to line up the cut close. Cut a little wide of the marks to start and make miter adjustments if necessary until the cut is perfect. See FHB #182 for pictures of technique.

Woodcraft makes a clamp kit similar to the Ulmia clamps for about $70. I've never tried a Clam Clamp in this situation, but it could work. You could only put one on the top and you'd have to back out the rear-most pin to prevent it splitting the fragile edge.

From contributor D:

I glue all my miters and use regular fiber strapping tape. Strapping tape is reinforced by the fibers and doesn't stretch. Tape the joint flat first and then install.

From Gary Katz, forum technical advisor:

You can't use the clam clamps on a 22 1/2 corner. I wouldn't attempt to use them on a 90 degree corner either, not on MDF. And even using the Collins Clamps will be tough. David is currently working on a new clamp design that will bite at that obtuse angle, but until they're available, I don't know of a clamp that will work. Ulmia's might bite, but they'll take out a big divot, especially on MDF.

I almost always assemble those pieces in place. If your outside corners aren't coming together tight, then something's up with your cuts. Even using hot glue or 2P10 won't solve that. Are you using a protractor to get the wall angles? If so, remember, when you adjust your miter saw to split the angle, if the corner reads 88 degrees, you want to cut a 44 degree miter and that means swinging the saw closer to the fence - the opposite direction that most miter gauges imply. The closer to the fence, the sharper the miter; the smaller the number on your protractor, the sharper the miter. Miter gauges aren't really finish-carpenter or protractor-friendly: 22 1/2 on your miter gauge is really 67 1/2 degrees.

From the original questioner:

Thanks. It's not really a problem of cut settings - even when I can't get the joint to close, it's a matter of 1/16th or less. It's also a race against time with the glue. Basically, I glue both sides of the outside 90 degree corner, shove the joint together, and put in a few nails near the center to hold up the molding. Of course, at least in my case, invariably there is enough of a gap to prevent a glue bond even if it's only 1/32nd. Usually the gap width is even across the joint and the faces of the molding are flush, indicating that my cuts are good. At that point all I can do is watch the glue dry.

Perhaps it's just something as simple as driving the first nails at an angle toward the joint to draw it together? Packing tape is not a bad idea, but may be hit or miss with 1" thick crown. Thanks for your patience.

From the original questioner:

An additional comment... Of course I dry fit the joint before gluing/nailing to insure the cut is good. Perhaps this sequence - glue joint, hold in place, nail through joint in 2 places with an 18 ga brad nailer, then nail crown to wall as usual? As I said before, even if the cut is perfect, if a gap opens up after nailing the crown to the wall, it's all over and even spring clamps or tape won't help. Or perhaps when I nail the crown to the wall I should compensate slightly and have the miter point a 16th or so long. Then a small tap on the crown will force the joint flush and a brad will seal the deal? Just thinking out loud here.

I'm missing a small detail that everyone probably takes for granted. Caulk in outside joints works well. In fact, I have never seen one open, but even at 1/16th or less wide, it's obvious.

From Gary Katz, forum technical advisor:

Yeah, I'd definitely start at the outside corner and get it nailed off very well before moving toward the middle. 18 ga and 23 ga nails are great, no matter what glue you're using.

If you're working alone, make or buy a couple of crown hangers. Fastcap sells them now in plastic. I've made a couple out of aluminum. You can set the crown in the hanger and work on the corners, then remove the hanger after the corners are finished. It's like working with a helper who always does what they're told and never distracts you with unnecessary conversation.

From the original questioner:

Usually alone. Great advice!

From Gary Katz, forum technical advisor:

I'm very glad to help. Just took a bit to figure out what was going on. Crown should be fun... always. It shouldn't be a fight. You did the right thing. If you're having a problem with it, stop and figure out a new way or technique, or ask somebody who has already spent years doing it the hard way (I'm not a fast learner)... so you don't have to.

From contributor S:

Titebond makes a glue for molding, that when you touch your miter ends together for about half a minute, you will have to snap it if you want it back apart. Ryobi makes some little vacuum based arms that will hold up to a smooth wall. There are several other gadgets that serve the same purpose. McFeelys.com has some for cheap. I like Collins miter clamps for this. A couple of 18 gauge brads will sometimes help you out too.

From contributor T:

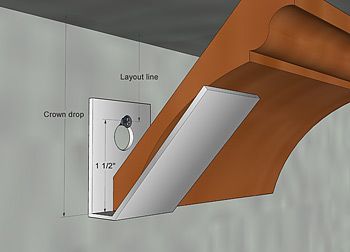

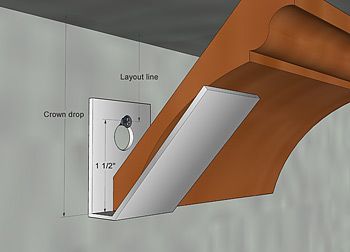

I hang a lot of crown, and I have found that there are three things that I like to do that help in quality and speed. First, I never use a brad nailer to install initially. I only use a Spotnails SP 2340 micro pinner, which shoots up to a 1 9/16" micro pin. This pin is strong enough to hold, but thin enough to move your crown or pull it off without ruining your piece.

Next, I cut my piece to length and hang it on the wall. I do this (on longer pieces) by placing a 16 penny nail in the wall just above the line of the bottom of the crown. I don't go into the stud, just the sheetrock, as I want this nail easily removable by hand when the time is appropriate. Say on a 12' piece where the right end is an outside corner, I will place the 16 pen nail about 2/3 of the way down the board (or 8 '). I then put the board up and check it for fit. (The trick here is to not have the piece you're fitting to be nailed or fastened so securely that you can't flex your angle slightly for a perfect fit.)

I then proceed to glue my corner, and use my micro pinner to secure it into place. The micro pins are so small that the hole left behind can not be detected in dark crown, or even in painted white crown if it is a high ceiling. (One swipe with a filler, and you won't even be able to tell where it is even when you're the one standing there doing the filling.)

After that, I go around with an appropriate fastener in the appropriate areas, and permanently fasten my crown. Another trick is to make feather shims, and stain them the same color as the crown. This is useful in old houses with lots of washboardy walls.