Creating Generic, Quickly Re-Sizeable Parts in AutoCAD

Here's advice on creating one simple file for, say, a door, that you can re-size as needed with a few commands or clicks. June 17, 2010

Question

I work in a shop running a CNC router, and I build mostly doors. I've started taking classes on AutoCAD hoping it would help me streamline my CNC programming. I haven't really been able to do what I want within AutoCAD (at least with the version I have).

Basically what I want to do is program a generic door, using standard sizes. I would then want to be able to select that door and type new measurements for the parts of the door, essentially changing the size of the door. I've been working with AutoCAD Mechanical and its part library, however I could free hand a door faster in PCDraft faster than I could figure out which parts I needed for my door and plug them in with AutoCAD. Does anyone know of any software that exists that can help me do this faster? (Hopefully a type of AutoCAD).

Forum Responses

(CAD Forum)

From contributor E:

What version of AutoCAD do you have because that will help narrow down what options are available to you. There are numerous things you can do, whether it be dynamic blocks, lisp routine, vba, action recorder, the new parametric stuff in 2010 etc. It really depends on what version and to some extent how complex your variations are. But it should definitely be doable in AutoCAD without too much effort.

From the original questioner:

I'm learning 2007 at school. I believe my company owns licensing for 2007 or 2008, however I personally have the student version of 2009 already downloaded. If it works I'm sure my company will buy it (AutoCAD). I would just need to download the student versions and see if really will work and present it to my boss. So if you recommend any of the AutoCad (or I guess also Autodesk) programs I can download them, try your suggestions, and if they work I can buy it.

From the original questioner:

Sorry, forgot to answer your second question. As far as complexity of variations, it would be along the lines of adjusting the XY dimensions of a part and having the other parts move to account for the resizing. I guess also adjusting radius' is a possibility.

From contributor O:

Have you tried AutoCAD 2010? It's now parametric and you can download a free demo from Autodesk. If not there are plenty of parametric programs out there both 2D and 3D. Inventor is a good value in a 3D modeler since it includes AutoCAD (but is an entirely different program).

From contributor E:

With 2007 or 2008 your best bet is probably to setup some dynamic blocks that have size parameters on them. With that you can have set intervals, sizes, or simply just whatever value you want. If you need to machine off of it once you get it to the right size simply explode the block. The most amount of effort is going to be in getting the block setup initially but they really are pretty simple. If you have a sample of a typical drawing with a variation or can give some more details I can make a sample dynamic block just so you can see the concept and whether that's what you're looking for or not.

From the original questioner:

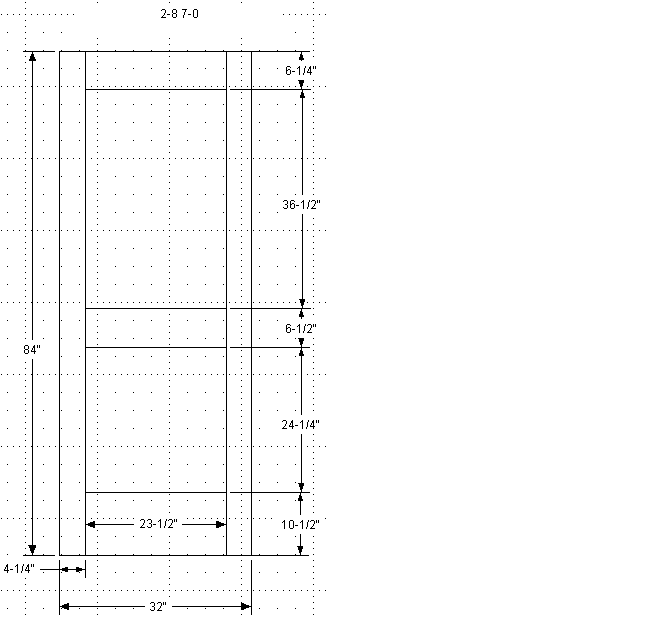

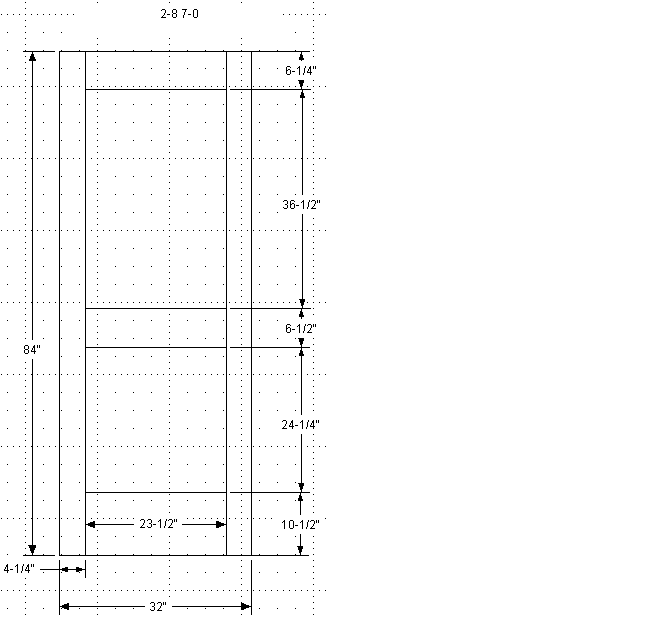

What exactly do you guys mean about Parametrics? (I will download 2010 and take a look at it). I'm attaching a sample picture of a really simple door. Basically I would want to save that as a generic two panel door, and then when I want to make a new two panel door (since we are very custom). I would like to be able to say "create two panel door" and adjust the sizes of all the parts very quickly (seconds). Also, as far as exploding, I haven't learned how to export programs to my CNC yet, however once I learn how to do that I imagine I would very much like to be able to explode these drawings into separate parts and send them to the CNC.

From contributor D:

Click here for higher quality, full size image

From contributor M:

You could save a lot of time if you just bypass all the drawing stuff and programming and create simple CNC parametric programs for your router, assuming you don't need door drawing for MRP or other systems. If you are building a five piece door you need to input only overall width and length and voila. You have your CNC program for each door piece. If you're making MDF doors it's even easier. It would help to know which router and controller do you run and what kind of doors you're building.

From the original questioner:

Well right now that is what I'm doing. I can essentially have a simple door programmed from my library in minutes, however I think my boss wants to lean towards software that will allow us to take our door drawing and create parts lists, find costs of production, etc. Something I know our CNC software can't do, but most CAD programs might be able to.

From contributor E:

A door like your sample you should be able to stretch just using standard AutoCAD commands very quickly so I would still recommend becoming proficient in AutoCAD, but doing the same thing repetitiously is crazy too. That said this could be simplified even more with 2010's parametric features of being able to constrain locations and sizes, etc. But that alone isn't a reason to upgrade if a previous version can do what you need.

From contributor E:

Oh and since you mention part lists, etc - AutoCAD has a tool called data extraction so you could fill up a drawing with a whole slew of different sized doors and extract the component sizes to excel fairly easily. There may be better solutions specifically for cutlisting doors, but Autocad can natively do at least that much and that might be enough for you without having to spend more on another software package.

From the original questioner:

I showed my boss and he was really excited. It would definitely make mass producing the same door in several different sizes much faster. So from there, I would just need to learn how to explode the parts, create a cut list, and price list, and I think I would be good to go. Thanks for your help! I'm only in semester one of my three semester course on AutoCAD at school, so hopefully I will be able to learn all the tricks over the next year or two.

From contributor W:

I just thought I would chime in here quick to say that I use Autodesk Inventor. I design steel and aluminum doors for my company. Using Inventor I am able to do exactly what you are talking about. I simply change my parameters and resize my doors, my drawings update automatically along with BOM, ect. Below is a link to my site where you can view a few small videos and animations to see some visual basic programming that I sometimes use to control my models. However vba is not something you will need to learn in order to use Inventor, it just makes it faster and easier to control things that you do repeatedly.

From contributor V:

If you like the dynamic block idea, which I think is a good strategy, here are a few ideas. Take your process and work back to the start. Figure out your final product and work backwards in order adding the things and features you need at each stage and add them. It will take time, but you should end up with a dynamic block you can insert and modify, then, depending on what you need, extract parts info (bom, finish, material), and explode it into CNC friendly entities (or copy and explode the copy). How automatic this is depends on how much time you spend and your skill level.

From the original questioner:

Thanks for the example from inventor. I keep reading descriptions on Autodesk.com about it, and I think it sounds like it could work, but then I am told itís completely different from AutoCAD and I probably wouldn't like it. How difficult is it to pick up inventor? Is doing what you did there really advanced, or is it pretty simple to do once you know how to use inventor?

Also, the way you skinned your model to look like actual wood. I assume you could click a button and change between different wood types and mix and match them with different stains if you spent the time to build your skin database?

From contributor W:

ďAlso, the way you skinned your model to look like actual wood, I assume you could click a button and change between different wood types and mix and match them with different stains if you spent the time to build your skin database?Ē Exactly! Learning Inventor is no different than learning any other software, it takes time and practice. Taking classes on Inventor are definitely advised. Once you use Inventor you will never go back to 2D layout in AutoCAD again.

From the original questioner:

With Inventor can you export individual parts to the CNC?

From contributor W:

We do not use Inventor with any type of CAM software. I do know that EdgeCam is used with Inventor, and I am sure there are others as well. Also you can save your Inventor 2D layout to a DWG and open it in AutoCAD. From there you could use a number of CNC- Cam software.

From contributor O:

With Inventor can you export individual parts to the CNC? Depending on your CAM software you won't have to export anything. MasterCAM, EdgeCAM and some others will bring in the 3D solid parts directly. This way the CNC programmer doesn't have to determine dado and hole depths, etc. These programs will also tell you if anything has changed in the geometry since you last programmed it.