Corner Cabinet Basics

Tips for a beginner on building corner cabinets. February 11, 2010

Question

I have built mostly built-ins, fireplace surrounds, and cabinets of that sort since I started in business six years ago. Now I am getting more requests for kitchen cabinets, which I somewhat hesitantly take on.

Can you give me some direction in how to build corner cabinets - 36" base, 24" and 27" uppers? I'd like to know how you build and fasten the face frames, the measurements for the carcasses, depth of dados, etc. I have fumbled my way through a number of them, and they turn out fine, but they take a long time and I know there must be some standards. I use 3/4" material for the sides, tops, and bottom and 1/2" or 3/4" for the back. I screw the carcass together when I can and use pocket screws on the face frames.

Forum Responses

(Cabinetmaking Forum)

From contributor J:

"The best measurement of anything is its actual measurement."

You have a method of construction. Draw a 36" square on a table and continue to draw it in life size scale from the back corner. Repeat for the 24 and 27" corner uppers. We actually made templates of this on 1/4 inch for teaching some years ago. With your experience you can do this.

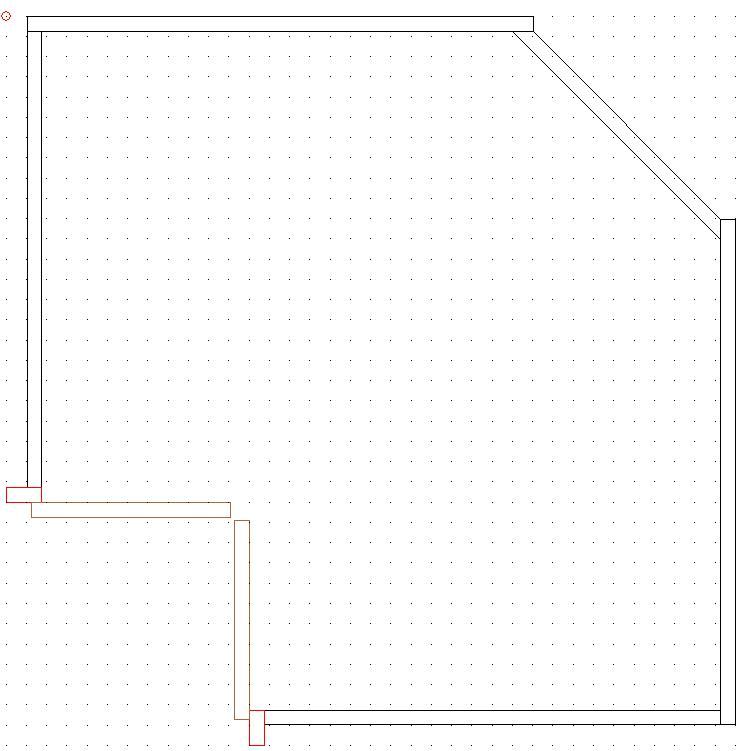

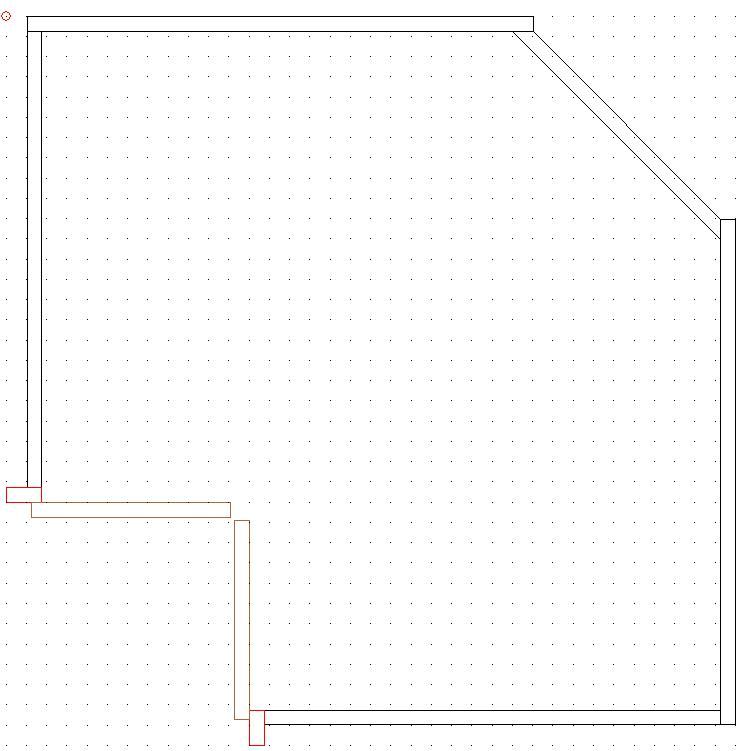

Click here for higher quality, full size image

From contributor L:

Corner cabinets are actually not that complicated once you get some standards established. We use a CAD program, so that also makes it easier. If you don't have a program, the template idea isn't a bad one. Here is a picture of how we construct base corner cabinets. We use 3/4" all the way around and 1/8" dadoes. Pocket holes to fasten face frame. We clip the back corner so the cabinet fits in the corner better.

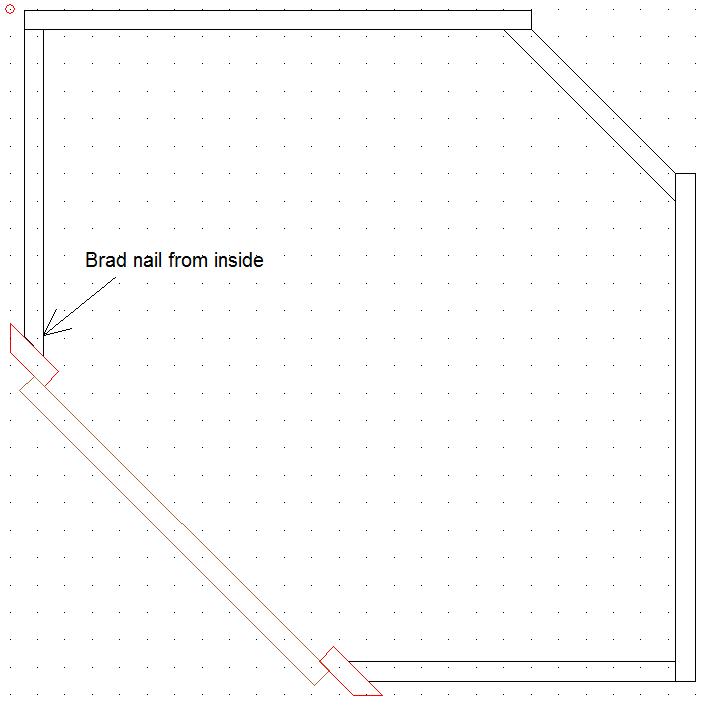

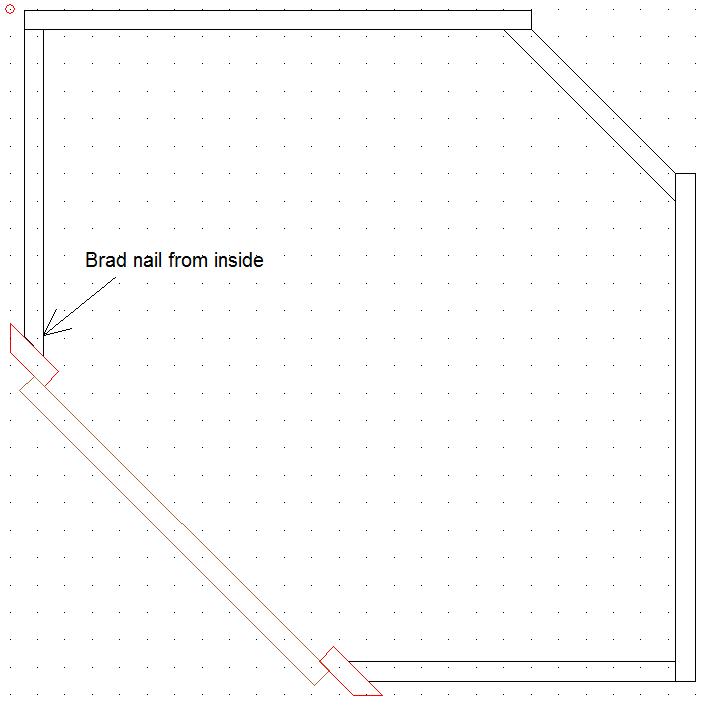

Click here for higher quality, full size image

Here is a picture of a diagonal corner upper. It works really well to fasten the face frame from the inside with brad nails as is shown.

Click here for higher quality, full size image

From the original questioner:

Thanks. I have thought about the template thing, but never have made one. Maybe I should... Do you guys cut a dado in the face frame?

From contributor L:

All we do is glue and screw or nail (clamp if needed).

From contributor B:

On an angled face I attach the face frame to the side with a rail and stile joint like you would build a door. The side is profiled with a male joint (I use the same cutter as a 1/4 rd bead for a door). The face frame stile is cut at a 45 degree using the female joint. This gives me instant alignment with about 1 1/2" of glue surface.

From the original questioner:

Huh, that joint in interesting. I guess you rip the 1X at a 45 on the table saw and make a jig for the shaper to hold the rail at 45 degrees also? Then I guess there would be a ridge left that would be sanded down. I like it.

From contributor B:

Actually the shaper cuts off all the wood without having to rip at 45 first. Maybe a picture of my fancy jig would be in line. It takes about 20-30 minutes to build. Then use it for years.