Question

When bending solid wood around a form, how do you calculate for springback?

Recently, a customer wanted me to make an architectural home theater. The top of the unit would be one big arch. The plan was to sunburst the arch and take a solid wood molding to meet the same arch of the top.

I was going to do it by laminating pieces together, but I don't know much about calculating springback. Do you also need to account for springback when making the jig, by overextending the radius so it goes past the points?

Forum Responses

(Solid Wood Machining Forum)

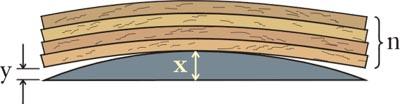

A number of plies of similar wood (n) are glued and clamped to a curved form, which is shaped to give the lamination a deflection of "x." When the clamps are removed, the lamination springs away from the form by an amount "y."

Springback can be predicted with the formula y = x/n2. The ratio of springback to the original deflection depends only on the number of laminations. The ratio does not depend on the properties or thickness of the wood or the geometry of the curved form. Thus, for two plies, the springback is one quarter of the initial deflection, or one ninth for three plies and one sixteenth for four plies.

Also, Woodcraft and Taunton both sell good books on the subject.

By "n" you mean "number of laminations."

By "y" you mean "amount of springback."

However, what do you mean by the form shape "will give the lamination a deflection of "x"? I would think the springback is the deflected amount.

Sorry, but could you explain this a bit more?