Question

I've done a bunch of research on the various computer software programs for doing cabinetry, but there seems to me a wide variety of programs for doing kitchens and such. I don't want to spend a huge amount for the software, as I only need a program that is user friendly, with real life looking pictures, and to just get the lay outs of a kitchen so the customer can see what they are getting. What do you suggest? And is it something I can buy at a store like Best Buy? Or is it best to just order it off the internet?

And what's this eCabinets deal? Been reading about it, but kind of confused as to what it all entails.

Forum Responses

(Cabinetmaking Forum)

From contributor K:

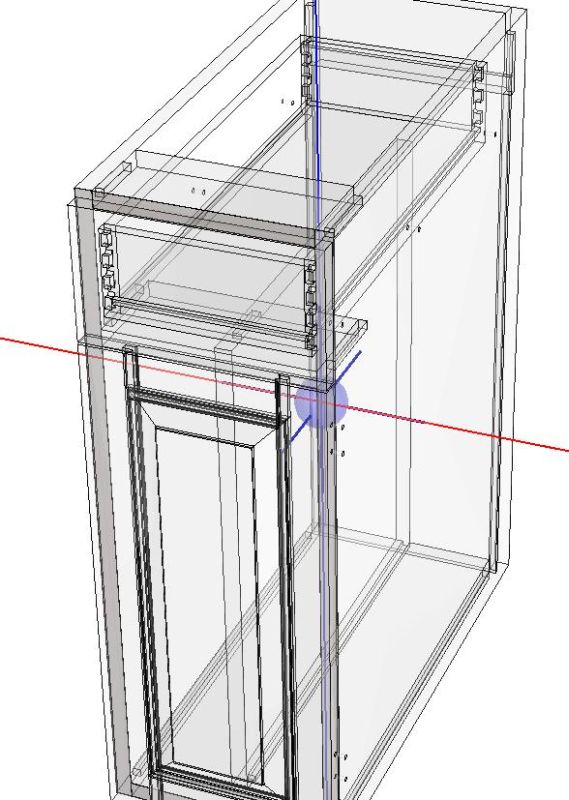

eCabinets is a free program that's distributed by Thermwood, a company that makes CNC routers. From what I understand it's the only program that will run their routers. It's arguably one of the most powerful cabinet design programs around and there's almost nothing you can't do with it. The problem is it has a huge learning curve and is not intuitive at all. If you can get past that, it can't be beat. eCabs beat me and I finally gave up but I'd suggest you get it and at least give it a try. If you can master it you will have everything you need for just your time as an investment.

I lease a program called Cabinet Solutions for $100 per month. It's about $3500 to buy. They have a free two week trial download. This is the simplest program I know of and gives great layout capability, cut lists, door lists, etc. I'd recommend it to anyone who's on a budget and needs design software. The 3D graphics leave a little to be desired but get the job done. Another program to consider is KCDw. It's a little more but has better graphics.

I don't know of anything you can buy through Best Buy.

For building and rendering interiors with cabinetry, the best bet might be the Better Homes and Gardens Pro Designer package, retailing for about $500. It is relatively easy to use, and can show rooms outfitted with accessory items other than cabinets. Changing surface colors and textures is easy. Pictures, yes, but it won't help you build anything.

I am sure that someone will come in here and show you a render done with eCabinets, and promote its features and benefits, and it may be what you need if you want production software beyond just rendering. eCabs can export CNC files for cutting parts, cutting lists for saw-shop operators without CNC gear, and more.

Everything has its learning curve and time expense, and with eCabs, it is high. You'll need to build a large library of cabinet types and doors and fronts styles, before you can begin populating a room with a layout. Personally, I don't like the renders you get using eCabs, and the whole lot of work it takes to insert all the bells and whistles beyond just the boxes, such as moldings, sinks, lighting, appliances, etc.

Google Sketchup is free and easy to learn, and will give good renderings, plus good dimensioned 2D plans and elevations. There are free plug-ins that yield excellent cutting lists and optimization. The thing that is super about Google SketchUp is its link to the Google 3D Warehouse, a repository of already-modeled components that can download right directly into your model. This aids greatly in the appliance end of things, because virtually all the majors have installed 3D images of their product lines in the 3D Warehouse. I find that clients like it when the pictures include good renderings of their selected gear.

With eCabs, I can email jobfiles to a production share shop that has a compatible (Thermwood) CNC router, and get all the parts made for a job. Everything comes flat-packed and all parts bear labels, and assembly is very fast. The software produces the output I need to buy out all the pre-finished doors, drawer fronts, and drawer boxes for the job.

If you already know how to use parameter-driven software like this (it is not a CAD program), learning eCabs might take a month or so, and that includes the time required to build the seed cabinet library you will use. Building a room with all the details of a kitchen, though, meaning moldings, corner legs, etc., can be tedious.

It has one fixed camera lens angle for viewing, and in my opinion, it is too narrow. Since it is free, it is relatively easy to try out and see how the rendering works for you, just by using the on-board generic boxes that are in the "base" library.

I wasnít certain how effective eCabinets was going to be, but I went ahead and started cutting my parts and organizing them on a set of shelves in the back of my shop. Once I had everything cut out, I held my breath and began to assemble everything. This project consisted of 66 carcasses totaling approximately 1000 pieces. Believe it or not only two pieces had to be re-cut and the project went pretty smooth.

I have been using eCabinets ever since. I have been very pleased with the product and the support the company has provided. I especially enjoy the forum available on their website for answering those more difficult questions.

The one thing you want to be aware of when it comes to graphic type software is the amount of computer power needed to accomplish your drawings and renderings. These types of software require a good processor and video card. eCabinets has a computer configuration recommendation on their site and you should try to get as close as possible. Anything less will be frustratingly slow.

eCabinets is a cooperative effort, and is paid by companies who sell products through eCabs software. You can buy many things related to cabinets - hinges, guides, hardware, doors, moulding - through links that are embedded in eCabs software. You are not required to purchase these things in order to use the software. It has a lot of features - it is powerful - but it takes a lot of time and practice to be able to navigate comfortably.

I started teaching myself AutoCAD when a 386/40 was a top of the line computer. This was helpful, but not practical. I tried eCabs in its infancy, but it had a lot of problems. As my need for a cutlist/design package increased, I spent more time with eCabs. It had a lot of problems, but improved with subsequent releases. It has developed into a very reliable program.

I chose to purchase a router, and you have to have software to run it. eCabs will only work with a Thermwood controller (Thermwood router). I bought an Onsrud and, naturally, needed another software program. After looking at several, let me give you a quick review.

There are some programs that are primarily visual, like Better Homes and Gardens. It will produce a pretty picture to scale, but does nothing to help you build cabinets... no cutlist and no estimating features. If you are just taking cabinets out of a box and screwing them to the wall, then this may be all that you need.

The next step up is a design package that will produce cutlists, and has some drafting capacity. Planit and Kcdw have programs like this. They have a library that you can use to put cabinets on the wall. You can modify the size of the cabinets, but it is not designed to make custom pieces like a curved vent hood or retail fixture. If you primarily work with residential cabinets, this may be all you need.

eCabs will allow you to make more modifications to cabinets. It is, however, very limited in its CAD abilities. Many find shop drawings to be very crude. It does have a good rendering package.

Microvellum uses AutoCAD and Excel to build cabinets, produce cutlists, and every imaginable kind of report. It is very powerful, very expensive, and has a lot of features that leads to a steep learning curve. It is capable of managing large commercial projects like a hospital with many floors.

If you need to get up and going quickly, try some of these packages that have a large library and will have you drawing in short order. There are several new programs in this category. Open up a copy of Cabinetmaker, or other trade magazine and start making calls.

If you are going to take eCabs for a drive, pay for the training. I did, and it was a good investment.

Microvellum may be something to consider for the future. It does have its place in the small shop, but probably not something to cut your teeth on. Having prior experience is not necessary, but it is helpful.

Comment from contributor R:

The big drawback we encountered is when you want to change the standard joint construction. Our shop did blind dado and that is not a standard joint type in their library. We had to go into the source files and change some coding and that was tedious although the technical support really helped us along in developing these files to fit our type of construction. Speaking of which, their tech support is excellent.

We used this with EnRoute and it was a solid CAD/CAM matchup. EnRoute was designed to integrate with KCDw and the pairing is almost seamless.

Like others were saying, this is a parametric program so you wonít be able to design your own super custom stuff. For a strictly CAD solution I've used SolidWorks, MasterCAM, and EnRoute. EnRoute is a bit of nightmare to do fancy solids. It can be done and I've drawn some custom moldings in it, but itís not as good as others to draw with. Doing CAD in MasterCAM is average I would say. It is incredibly powerful and flexible but the learning curve is steep. That being said, you would never buy it to do just CAD (I do enjoy its toolpathing algorithms though). SolidWorks is by far the best 3D modeling CAD software that I have tried but definitely overkill for a cabinet shop's needs.