roughed out blank on CNC

Done on CNC. Really stressed out over this part. One error and the blank is ruined. Client brought in lumber. I had the CNC dish out the material so it was bowel shaped. To keep items on table from sliding off and or spills contained. Also had CNC rough out star.

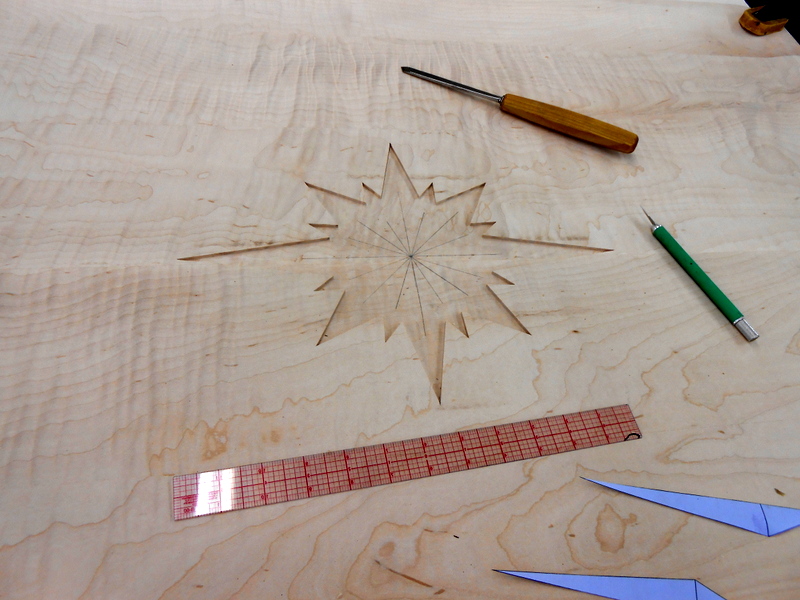

Preparing star for inlay work

Starting the inlay work. Fun but tedious.

More on inlay

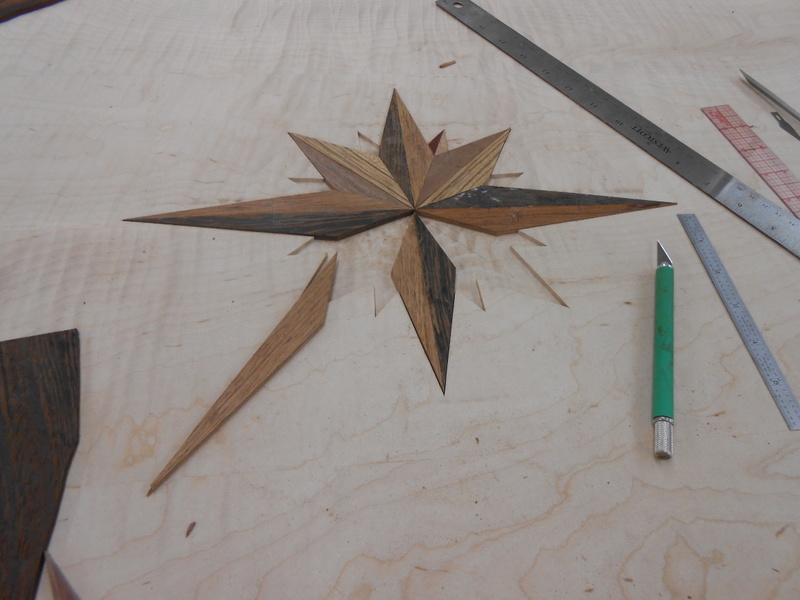

Finished inlay

Close up of work. Woods are Wenge, Zebra Wood, walnut, Jakarta, Rosewood, and burl Maple

Table with finish. Client wanted a clear finish no stain. I would have liked to add a little something to make the curls pop more like the next picture. This table had to match other work on the boat.

I would have liked to had a lighter version of this to show off the wood curls more

table on boat

Finished and installed. We christened it with a very nice Scotch. So it was fully tested and ready for service. It was a dirty job, but someone had to do that initial testing.